Annual Report 1999 - Kemira

Annual Report 1999 - Kemira

Annual Report 1999 - Kemira

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

certificates. The Lauterbourg plant in<br />

France is preparing for certification in<br />

2000. The Prerov plant in the Czech<br />

Republic obtained endorsement for the<br />

Responsible Care programme.<br />

At the Siilinjärvi plants in Finland, a<br />

safety assessment was conducted according<br />

to the ISRS (International Safety<br />

Rating) system. The Oulu plant continued<br />

to incorporate ISO 14001 into<br />

the overall management system.<br />

<strong>Kemira</strong> Pigments reached the voluntary<br />

targets set in the EMS system of<br />

the Pori plant in Finland. The plant<br />

also passed a safety audit according to<br />

the Seveso II directive and started application<br />

of the safety management<br />

system. At <strong>Kemira</strong> Pigments B.V., Rotterdam,<br />

the Netherlands, authority approval<br />

was obtained for the company<br />

environmental plan and a safety programme<br />

was started with the aim of<br />

fulfilling the national implementation<br />

of the Seveso II directive.<br />

<strong>Kemira</strong> Agro started developing<br />

ISO 14001 for all major fertilizer plants<br />

in Europe. The Tertre plant in Belgium<br />

expects to be certified in 2000 and the<br />

Rozenburg plant in the Netherlands<br />

started a similar development effort.<br />

ENVIRONMENT PROTECTION AT<br />

THE PRODUCTION PLANTS<br />

<strong>Kemira</strong> Chemicals. <strong>Kemira</strong> Kemi AB,<br />

Helsingborg, Sweden, successfully investigated<br />

possibilities for reducing<br />

waste to landfills. A permit was obtained<br />

for using significant amounts of<br />

waste and by-products as alternative<br />

raw materials. Permits to expand hydrochloric<br />

acid production were also<br />

issued. The planned expansion includes<br />

the construction of a new treatment<br />

plant for reducing the HCl emissions.<br />

The Ulsan hydrogen peroxide plant<br />

in South Korea reduced energy and<br />

solvent consumption substantially by<br />

changing operational conditions. The<br />

Maitland plant in Canada completed a<br />

VOC survey and an environmental risk<br />

assessment, and it obtained a waste<br />

generation permit. Steam is now purchased<br />

from a neighbouring company,<br />

which is also responsible for associated<br />

emissions.<br />

The Kemwater business unit reduced<br />

waste at Kvarntorp, Sweden, by<br />

starting the recycling of acidic sludge<br />

filtrate. The total recycling of aluminium<br />

hydrate allowed the Police plant in<br />

Poland to reach zero process waste<br />

disposal. The Rozenburg plant in the<br />

Netherlands also minimized waste by<br />

increasing its filtration capacity. The<br />

Fredrikstad plant in Norway renewed<br />

chlorine detectors. The Prerov plant in<br />

the Czech Republic obtained permits<br />

to double capacity and improved safety<br />

control.<br />

<strong>Kemira</strong> Chemicals B.V., Rozenburg,<br />

completed five environmental improvement<br />

projects mainly to reduce<br />

VOC, noise and waste. A new chemical<br />

storage was also built.<br />

The Oulu plants in Finland made<br />

improvements in odour and noise control<br />

as well as in safety equipment. Recycling<br />

of aluminum oxide and further<br />

processing of soot were investigated.<br />

The plant also obtained a waste management<br />

permit and submitted an application<br />

for a renewal of the waste<br />

water permit.<br />

At the Siilinjärvi plants and mine in<br />

Finland, the extensive renovation of<br />

phosphoric acid and energy production<br />

facilities improved environmental<br />

and safety controls. Air and water releases<br />

remained very low, and enhanced<br />

water recycling diminished nitrogen<br />

discharges below target values.<br />

The plant also obtained a renewed<br />

waste water permit and an important<br />

new waste management permit. The<br />

latter, even if still not final, may impose<br />

new requirements for the rehabilitation<br />

of the piling and storage of areas<br />

for by-products and waste.<br />

The Kokkola plant completed demolition<br />

of an old sulphuric acid unit,<br />

and removed 10,400 m 3 of surface soil<br />

that was contaminated with mercury<br />

for final off-site disposal. In addition, a<br />

soil and ground water survey of heavy<br />

metals was conducted on the whole<br />

site without significant new findings.<br />

Sulphur emissions increased by one<br />

third due to temporary heat exchanger<br />

problems at the sulphuric acid plant.<br />

<strong>Kemira</strong> Pigments. <strong>Kemira</strong> Pigments<br />

Inc., Savannah, made numerous modifications<br />

to prevent low pH excursions<br />

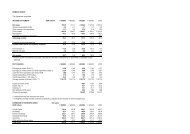

Figure 4 Figure 5 Figure 6<br />

SULPHUR EMISSIONS<br />

HEAVY METAL DISCHARGES<br />

NITROGEN DISCHARGES<br />

Other countries<br />

Finland<br />

Tonnes<br />

45000<br />

Tonnes<br />

50<br />

Other countries<br />

Finland<br />

Tonnes<br />

3000<br />

40000<br />

35000<br />

40<br />

2500<br />

30000<br />

25000<br />

20000<br />

15000<br />

30<br />

20<br />

2000<br />

1500<br />

1000<br />

10000<br />

5000<br />

10<br />

500<br />

80 90 91 92 93 94 95 96 97 98 99<br />

All sulphur compounds calculated as SO 2 .<br />

0<br />

90 91 92 93 94 95 96 97 98 99<br />

Sum of five different heavy metals,<br />

mostly chromium.<br />

0<br />

90 91 92 93 94 95 96 97 98 99<br />

0<br />

55