Activity Report 2010 - CNRS

Activity Report 2010 - CNRS

Activity Report 2010 - CNRS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

9 – TECHNOLOGICAL<br />

FACILITIES<br />

Created at the early stage of the<br />

Nanosciences Foundation in 2006, the<br />

“network of technological facilities”<br />

gathers most of the facilities concerned<br />

by nanofabrication, characterization at<br />

nanoscale, simulation and modeling of<br />

nanostructures, within the scientific area<br />

covered by the Foundation. The network<br />

is aimed to coordinate the financial<br />

support provided by the Foundation to<br />

the facilities. By supporting running costs<br />

of some facilities, the Foundation also<br />

eases the access to shared equipments.<br />

With almost 1/3 of its budget dedicated<br />

to the network of technological facilities,<br />

the Foundation contributes efficiently to<br />

the development of nanotechnologies<br />

involving physics, chemistry and biology.<br />

The facilities are opened to the whole<br />

community of researchers, post doctoral<br />

fellows and students involved in<br />

nanosciences. They offer state-of-the-art<br />

equipments for nanofabrication,<br />

nanocharacterisation and numerical<br />

simulation. More than 80% of the overall<br />

projects supported by the Foundation<br />

uses or have used the equipments of the<br />

network and many other national and<br />

European projects also benefits from<br />

them.<br />

THE NETWORK<br />

The network is composed by four<br />

facilities dedicated to:<br />

Nanofabrication<br />

Nanocharacterization<br />

Nano-chemistry and biology<br />

Numerical simulation<br />

The Nanofabrication Facility<br />

This Nanofabrication facility covers 1000<br />

m 2 dispatched over two clean rooms<br />

located in close proximity. These clean<br />

rooms offer top level equipments for<br />

optical and electron beam lithography,<br />

metals and oxides deposition, reactive<br />

ion etching, chemical cleaning and<br />

etching, characterization and metrology.<br />

They are specially equipped to process<br />

samples of various sizes (from millimetre<br />

up to 4 inches). Special procedures have<br />

been implemented to avoid cross<br />

contamination as different types of<br />

materials (semiconductors, metals and<br />

polymers) can be processed in the<br />

facility. This flexibility is particularly<br />

important to provide a full access to the<br />

networks members.<br />

PTA:<br />

The Plateforme Technologique Amont<br />

(PTA) operated by CEA, <strong>CNRS</strong>, Grenoble<br />

INP and UJF and located on the MINATEC<br />

campus, provides to the community upto-date<br />

equipments for nanofabrication<br />

including electron beam lithography,<br />

etching (ion beams, reactive plasma) and<br />

deposition. The main topics developed in<br />

the PTA deal with nanoelectronics,<br />

spintronics, and photonics. Since 2009<br />

and thanks to the merger of PTA and<br />

CIME Nanotech clean rooms, the PTA<br />

provides also equipments dedicated to<br />

the fabrication of Micro-Electro<br />

Mechanical Systems (MEMS).<br />

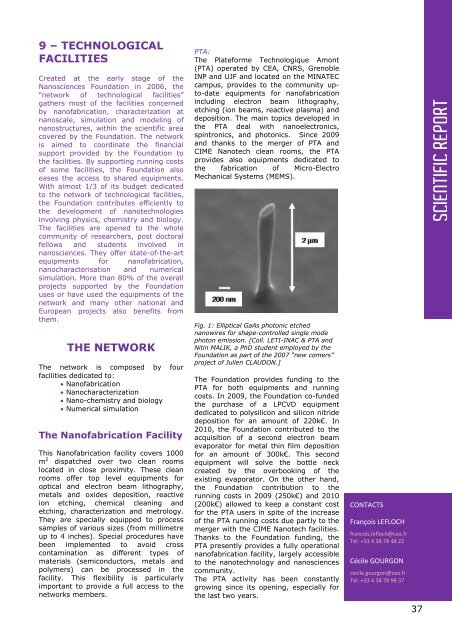

Fig. 1: Elliptical GaAs photonic etched<br />

nanowires for shape-controlled single mode<br />

photon emission. [Coll. LETI-INAC & PTA and<br />

Nitin MALIK, a PhD student employed by the<br />

Foundation as part of the 2007 “new comers”<br />

project of Julien CLAUDON.]<br />

The Foundation provides funding to the<br />

PTA for both equipments and running<br />

costs. In 2009, the Foundation co-funded<br />

the purchase of a LPCVD equipment<br />

dedicated to polysilicon and silicon nitride<br />

deposition for an amount of 220k€. In<br />

<strong>2010</strong>, the Foundation contributed to the<br />

acquisition of a second electron beam<br />

evaporator for metal thin film deposition<br />

for an amount of 300k€. This second<br />

equipment will solve the bottle neck<br />

created by the overbooking of the<br />

existing evaporator. On the other hand,<br />

the Foundation contribution to the<br />

running costs in 2009 (250k€) and <strong>2010</strong><br />

(200k€) allowed to keep a constant cost<br />

for the PTA users in spite of the increase<br />

of the PTA running costs due partly to the<br />

merger with the CIME Nanotech facilities.<br />

Thanks to the Foundation funding, the<br />

PTA presently provides a fully operational<br />

nanofabrication facility, largely accessible<br />

to the nanotechnology and nanosciences<br />

community.<br />

The PTA activity has been constantly<br />

growing since its opening, especially for<br />

the last two years.<br />

CONTACTS<br />

François LEFLOCH<br />

francois.lefloch@cea.fr<br />

Tel: +33 4 38 78 48 22<br />

Cécile GOURGON<br />

cecile.gourgon@cea.fr<br />

Tel: +33 4 38 78 98 37<br />

37<br />

SCIENTIFIC REPORT