WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

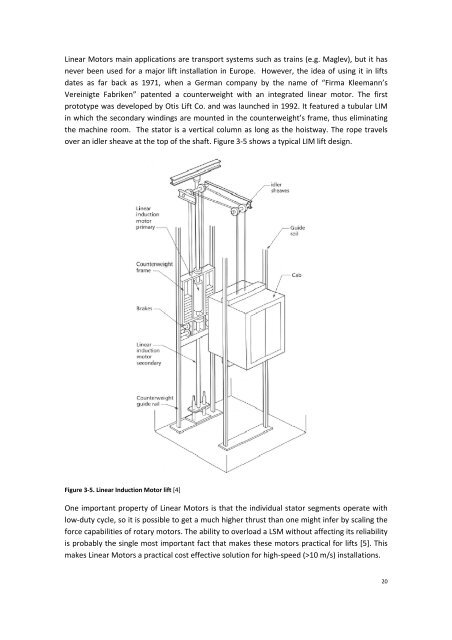

Linear Motors main applications are transport systems such as trains (e.g. Maglev), but it has<br />

never been used for a major lift installation in Europe. However, the idea of using it in lifts<br />

dates as far back as 1971, when a German company by the name of “Firma Kleemann’s<br />

Vereinigte Fabriken” patented a counterweight with an integrated linear motor. The first<br />

prototype was developed by Otis <strong>Lift</strong> Co. and was launched in 1992. It featured a tubular LIM<br />

in which the secondary windings are mounted in the counterweight’s frame, thus eliminating<br />

the machine room. The stator is a vertical column as long as the hoistway. The rope travels<br />

over an idler sheave at the top of the shaft. Figure 3‐5 shows a typical LIM lift design.<br />

Figure 3‐5. Linear Induction Motor lift [4]<br />

One important property of Linear Motors is that the individual stator segments operate with<br />

low‐duty cycle, so it is possible to get a much higher thrust than one might infer by scaling the<br />

force capabilities of rotary motors. The ability to overload a LSM without affecting its reliability<br />

is probably the single most important fact that makes these motors practical for lifts [5]. This<br />

makes Linear Motors a practical cost effective solution for high‐speed (>10 m/s) installations.<br />

20