WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

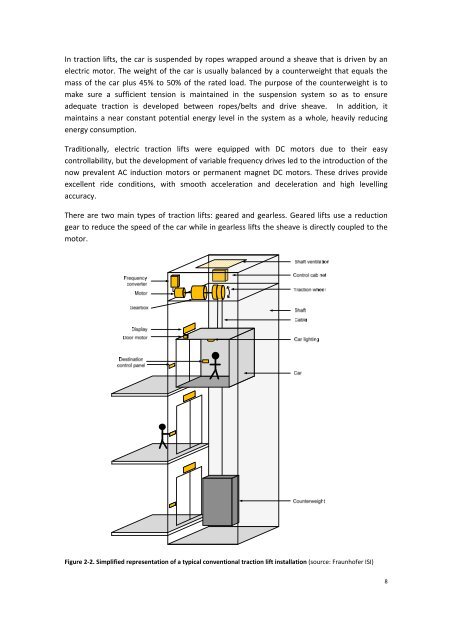

In traction lifts, the car is suspended by ropes wrapped around a sheave that is driven by an<br />

electric motor. The weight of the car is usually balanced by a counterweight that equals the<br />

mass of the car plus 45% to 50% of the rated load. The purpose of the counterweight is to<br />

make sure a sufficient tension is maintained in the suspension system so as to ensure<br />

adequate traction is developed between ropes/belts and drive sheave. In addition, it<br />

maintains a near constant potential energy level in the system as a whole, heavily reducing<br />

energy consumption.<br />

Traditionally, electric traction lifts were equipped with DC motors due to their easy<br />

controllability, but the development of variable frequency drives led to the introduction of the<br />

now prevalent AC induction motors or permanent magnet DC motors. These drives provide<br />

excellent ride conditions, with smooth acceleration and deceleration and high levelling<br />

accuracy.<br />

There are two main types of traction lifts: geared and gearless. Geared lifts use a reduction<br />

gear to reduce the speed of the car while in gearless lifts the sheave is directly coupled to the<br />

motor.<br />

Figure 2‐2. Simplified representation of a typical conventional traction lift installation (source: Fraunhofer ISI)<br />

8