WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

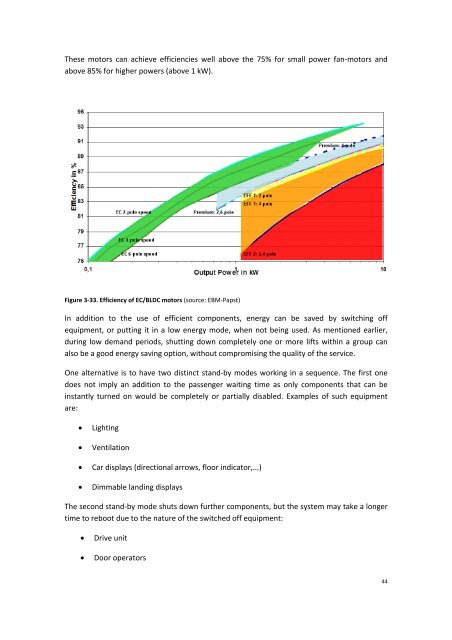

These motors can achieve efficiencies well above the 75% for small power fan‐motors and<br />

above 85% for higher powers (above 1 kW).<br />

Figure 3‐33. Efficiency of EC/BLDC motors (source: EBM‐Papst)<br />

In addition to the use of efficient components, energy can be saved by switching off<br />

equipment, or putting it in a low energy mode, when not being used. As mentioned earlier,<br />

during low demand periods, shutting down completely one or more lifts within a group can<br />

also be a good energy saving option, without compromising the quality of the service.<br />

One alternative is to have two distinct stand‐by modes working in a sequence. The first one<br />

does not imply an addition to the passenger waiting time as only components that can be<br />

instantly turned on would be completely or partially disabled. Examples of such equipment<br />

are:<br />

• Lighting<br />

• Ventilation<br />

• Car displays (directional arrows, floor indicator,...)<br />

• Dimmable landing displays<br />

The second stand‐by mode shuts down further components, but the system may take a longer<br />

time to reboot due to the nature of the switched off equipment:<br />

• Drive unit<br />

• Door operators<br />

44