WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

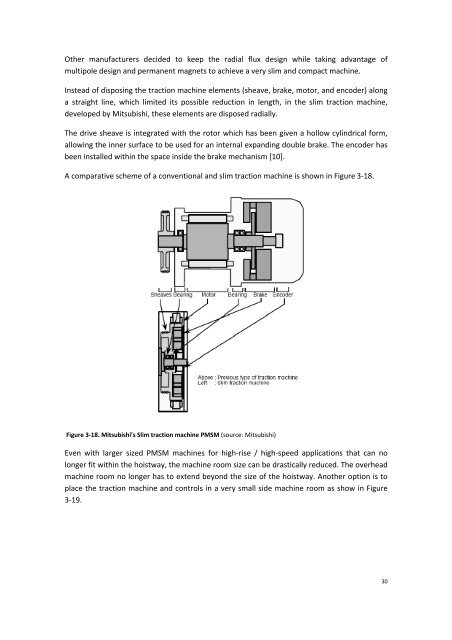

Other manufacturers decided to keep the radial flux design while taking advantage of<br />

multipole design and permanent magnets to achieve a very slim and compact machine.<br />

Instead of disposing the traction machine elements (sheave, brake, motor, and encoder) along<br />

a straight line, which limited its possible reduction in length, in the slim traction machine,<br />

developed by Mitsubishi, these elements are disposed radially.<br />

The drive sheave is integrated with the rotor which has been given a hollow cylindrical form,<br />

allowing the inner surface to be used for an internal expanding double brake. The encoder has<br />

been installed within the space inside the brake mechanism [10].<br />

A comparative scheme of a conventional and slim traction machine is shown in Figure 3‐18.<br />

Figure 3‐18. Mitsubishi’s Slim traction machine PMSM (source: Mitsubishi)<br />

Even with larger sized PMSM machines for high‐rise / high‐speed applications that can no<br />

longer fit within the hoistway, the machine room size can be drastically reduced. The overhead<br />

machine room no longer has to extend beyond the size of the hoistway. Another option is to<br />

place the traction machine and controls in a very small side machine room as show in Figure<br />

3‐19.<br />

30