WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

WP6-Brochure-E4 brochure - ELA European Lift Association.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

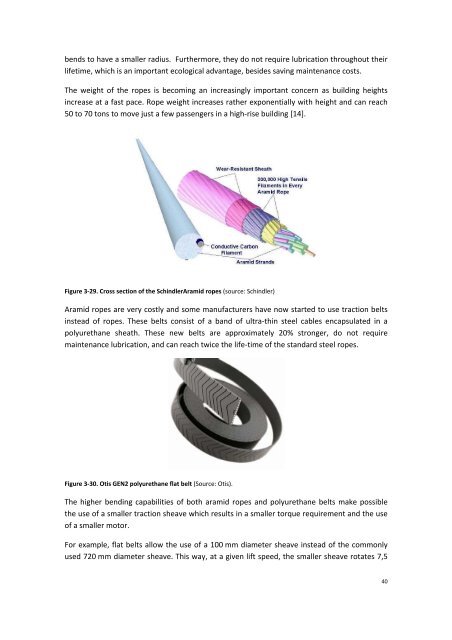

ends to have a smaller radius. Furthermore, they do not require lubrication throughout their<br />

lifetime, which is an important ecological advantage, besides saving maintenance costs.<br />

The weight of the ropes is becoming an increasingly important concern as building heights<br />

increase at a fast pace. Rope weight increases rather exponentially with height and can reach<br />

50 to 70 tons to move just a few passengers in a high‐rise building [14].<br />

Figure 3‐29. Cross section of the SchindlerAramid ropes (source: Schindler)<br />

Aramid ropes are very costly and some manufacturers have now started to use traction belts<br />

instead of ropes. These belts consist of a band of ultra‐thin steel cables encapsulated in a<br />

polyurethane sheath. These new belts are approximately 20% stronger, do not require<br />

maintenance lubrication, and can reach twice the life‐time of the standard steel ropes.<br />

Figure 3‐30. Otis GEN2 polyurethane flat belt (Source: Otis).<br />

The higher bending capabilities of both aramid ropes and polyurethane belts make possible<br />

the use of a smaller traction sheave which results in a smaller torque requirement and the use<br />

of a smaller motor.<br />

For example, flat belts allow the use of a 100 mm diameter sheave instead of the commonly<br />

used 720 mm diameter sheave. This way, at a given lift speed, the smaller sheave rotates 7,5<br />

40