Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

APPLICATIONS<br />

SYSTEM7<br />

SYSTEM<br />

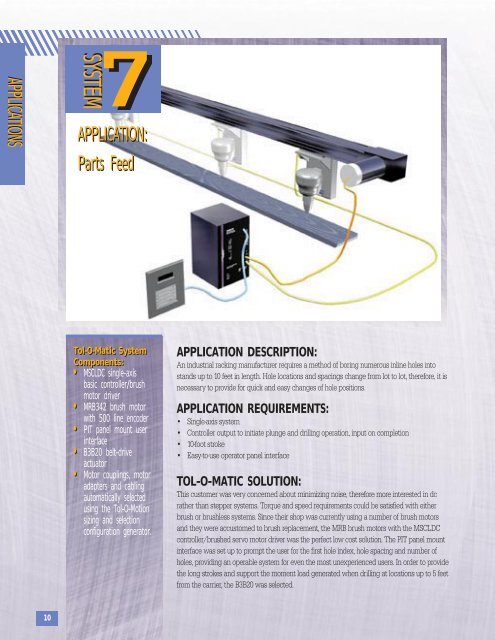

APPLICATION:<br />

Parts Feed<br />

<strong>Tol</strong>-O-<strong>Matic</strong> <strong>System</strong><br />

Components:<br />

• MSCLDC single-axis<br />

basic controller/brush<br />

motor driver<br />

• MRB342 brush motor<br />

with 500 line encoder<br />

• PIT panel mount user<br />

interface<br />

• B3B20 belt-drive<br />

actuator<br />

• Motor couplings, motor<br />

adapters <strong>and</strong> cabling<br />

automatically selected<br />

using the <strong>Tol</strong>-O-Motion<br />

sizing <strong>and</strong> selection<br />

configuration generator.<br />

APPLICATION DESCRIPTION:<br />

An industrial racking manufacturer requires a method of boring numerous inline holes into<br />

st<strong>and</strong>s up to 10 feet in length. Hole locations <strong>and</strong> spacings change from lot to lot, therefore, it is<br />

necessary to provide for quick <strong>and</strong> easy changes of hole positions.<br />

APPLICATION REQUIREMENTS:<br />

• Single-axis system<br />

• Controller output to initiate plunge <strong>and</strong> drilling operation, input on completion<br />

• 10-foot stroke<br />

• Easy-to-use operator panel interface<br />

TOL-O-MATIC SOLUTION:<br />

This customer was very concerned about minimizing noise, therefore more interested in dc<br />

rather than stepper systems. Torque <strong>and</strong> speed requirements could be satisfied with either<br />

brush or brushless systems. Since their shop was currently using a number of brush motors<br />

<strong>and</strong> they were accustomed to brush replacement, the MRB brush motors with the MSCLDC<br />

controller/brushed servo motor driver was the perfect low cost solution. The PIT panel mount<br />

interface was set up to prompt the user for the first hole index, hole spacing <strong>and</strong> number of<br />

holes, providing an operable system for even the most unexperienced users. In order to provide<br />

the long strokes <strong>and</strong> support the moment load generated when drilling at locations up to 5 feet<br />

from the carrier, the B3B20 was selected.<br />

10