Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

APPLICATIONS<br />

SYSTEM3<br />

SYSTEM<br />

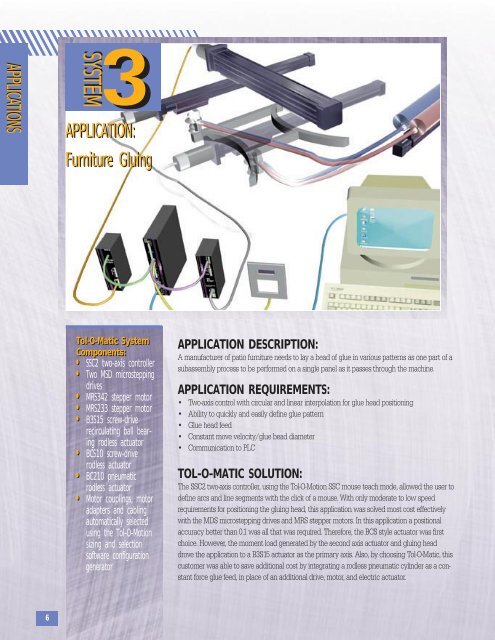

APPLICATION:<br />

Furniture Gluing<br />

<strong>Tol</strong>-O-<strong>Matic</strong> <strong>System</strong><br />

Components:<br />

• SSC2 two-axis controller<br />

• Two MSD microstepping<br />

drives<br />

• MRS342 stepper motor<br />

• MRS233 stepper motor<br />

• B3S15 screw-drive<br />

recirculating ball bearing<br />

rodless actuator<br />

• BCS10 screw-drive<br />

rodless actuator<br />

• BC210 pneumatic<br />

rodless actuator<br />

• Motor couplings, motor<br />

adapters <strong>and</strong> cabling<br />

automatically selected<br />

using the <strong>Tol</strong>-O-Motion<br />

sizing <strong>and</strong> selection<br />

software configuration<br />

generator<br />

APPLICATION DESCRIPTION:<br />

A manufacturer of patio furniture needs to lay a bead of glue in various patterns as one part of a<br />

subassembly process to be performed on a single panel as it passes through the machine.<br />

APPLICATION REQUIREMENTS:<br />

• Two-axis control with circular <strong>and</strong> linear interpolation for glue head positioning<br />

• Ability to quickly <strong>and</strong> easily define glue pattern<br />

• Glue head feed<br />

• Constant move velocity/glue bead diameter<br />

• Communication to PLC<br />

TOL-O-MATIC SOLUTION:<br />

The SSC2 two-axis controller, using the <strong>Tol</strong>-O-Motion SSC mouse teach mode, allowed the user to<br />

define arcs <strong>and</strong> line segments with the click of a mouse. With only moderate to low speed<br />

requirements for positioning the gluing head, this application was solved most cost effectively<br />

with the MDS microstepping drives <strong>and</strong> MRS stepper motors. In this application a positional<br />

accuracy better than 0.1 was all that was required. Therefore, the BCS style actuator was first<br />

choice. However, the moment load generated by the second axis actuator <strong>and</strong> gluing head<br />

drove the application to a B3S15 actuator as the primary axis. Also, by choosing <strong>Tol</strong>-O-<strong>Matic</strong>, this<br />

customer was able to save additional cost by integrating a rodless pneumatic cylinder as a constant<br />

force glue feed, in place of an additional drive, motor, <strong>and</strong> electric actuator.<br />

6