Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Tol-O-Matic System Compatibility - Industrial and Bearing Supplies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

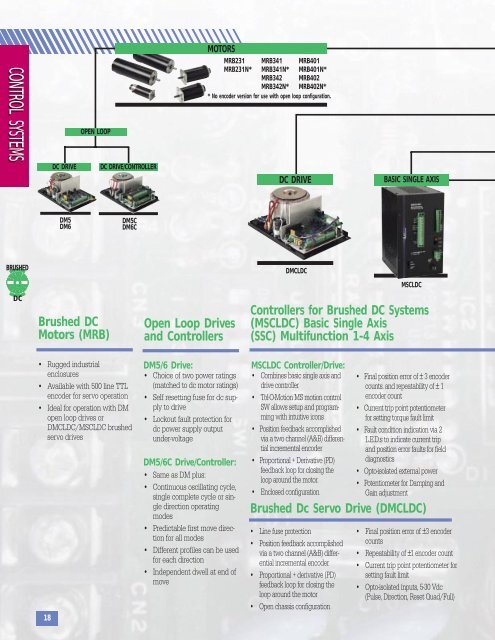

CONTROL SYSTEMS<br />

OPEN LOOP<br />

MOTORS<br />

MRB231<br />

MRB231N*<br />

MRB341<br />

MRB341N*<br />

MRB342<br />

MRB342N*<br />

MRB401<br />

MRB401N*<br />

MRB402<br />

MRB402N*<br />

* No encoder version for use with open loop configuration.<br />

DC DRIVE<br />

DC DRIVE/CONTROLLER<br />

DC DRIVE<br />

BASIC SINGLE AXIS<br />

DM5<br />

DM6<br />

DM5C<br />

DM6C<br />

DMCLDC<br />

MSCLDC<br />

Brushed DC<br />

Motors (MRB)<br />

Open Loop Drives<br />

<strong>and</strong> Controllers<br />

Controllers for Brushed DC <strong>System</strong>s<br />

(MSCLDC) Basic Single Axis<br />

(SSC) Multifunction 1-4 Axis<br />

• Rugged industrial<br />

enclosures<br />

• Available with 500 line TTL<br />

encoder for servo operation<br />

• Ideal for operation with DM<br />

open loop drives or<br />

DMCLDC/MSCLDC brushed<br />

servo drives<br />

18<br />

DM5/6 Drive:<br />

• Choice of two power ratings<br />

(matched to dc motor ratings)<br />

• Self resetting fuse for dc supply<br />

to drive<br />

• Lockout fault protection for<br />

dc power supply output<br />

under-voltage<br />

DM5/6C Drive/Controller:<br />

• Same as DM plus:<br />

• Continuous oscillating cycle,<br />

single complete cycle or single<br />

direction operating<br />

modes<br />

• Predictable first move direction<br />

for all modes<br />

• Different profiles can be used<br />

for each direction<br />

• Independent dwell at end of<br />

move<br />

MSCLDC Controller/Drive:<br />

• Combines basic single axis <strong>and</strong><br />

drive controller<br />

• <strong>Tol</strong>-O-Motion MS motion control<br />

SW allows setup <strong>and</strong> programming<br />

with intuitive icons<br />

• Position feedback accomplished<br />

via a two channel (A&B) differential<br />

incremental encoder<br />

• Proportional + Derivative (PD)<br />

feedback loop for closing the<br />

loop around the motor.<br />

• Enclosed configuration<br />

• Final position error of ± 3 encoder<br />

counts. <strong>and</strong> repeatability of ± 1<br />

encoder count<br />

• Current trip point potentiometer<br />

for setting torque fault limit<br />

• Fault condition indication via 2<br />

L.E.D.s to indicate current trip<br />

<strong>and</strong> position error faults for field<br />

diagnostics<br />

• Opto-isolated external power<br />

• Potentiometer for Damping <strong>and</strong><br />

Gain adjustment<br />

Brushed Dc Servo Drive (DMCLDC)<br />

• Line fuse protection<br />

• Position feedback accomplished<br />

via a two channel (A&B) differential<br />

incremental encoder<br />

• Proportional + derivative (PD)<br />

feedback loop for closing the<br />

loop around the motor<br />

• Open chassis configuration<br />

• Final position error of ±3 encoder<br />

counts<br />

• Repeatability of ±1 encoder count<br />

• Current trip point potentiometer for<br />

setting fault limit<br />

• Opto-isolated inputs, 5-30 Vdc<br />

(Pulse, Direction, Reset Quad/Full)