FLENDER Standard Couplings - DS TECH

FLENDER Standard Couplings - DS TECH

FLENDER Standard Couplings - DS TECH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>FLENDER</strong> <strong>Standard</strong> <strong>Couplings</strong><br />

Coupling Preselection and Options<br />

© Siemens AG 2011<br />

Selection of the coupling series<br />

3<br />

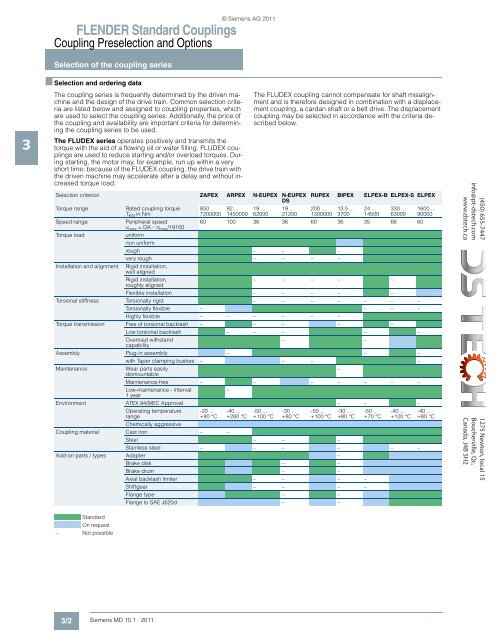

■ Selection and ordering data<br />

The coupling series is frequently determined by the driven machine<br />

and the design of the drive train. Common selection criteria<br />

are listed below and assigned to coupling properties, which<br />

are used to select the coupling series. Additionally, the price of<br />

the coupling and availability are important criteria for determining<br />

the coupling series to be used.<br />

The FLUDEX series operates positively and transmits the<br />

torque with the aid of a flowing oil or water filling. FLUDEX couplings<br />

are used to reduce starting and/or overload torques. During<br />

starting, the motor may, for example, run up within a very<br />

short time; because of the FLUDEX coupling, the drive train with<br />

the driven machine may accelerate after a delay and without increased<br />

torque load.<br />

Selection criterion ZAPEX ARPEX N-EUPEX N-EUPEX<br />

<strong>DS</strong><br />

Torque range<br />

Speed range<br />

Rated coupling torque<br />

T KN in Nm<br />

Peripheral speed<br />

v max = DA ⋅ n max /19100<br />

850 ...<br />

7200000<br />

92 ...<br />

1450000<br />

The FLUDEX coupling cannot compensate for shaft misalignment<br />

and is therefore designed in combination with a displacement<br />

coupling, a cardan shaft or a belt drive. The displacement<br />

coupling may be selected in accordance with the criteria described<br />

below.<br />

19 ...<br />

62000<br />

19 ...<br />

21200<br />

RUPEX BIPEX ELPEX-B ELPEX-S ELPEX<br />

200 ...<br />

1300000<br />

13.5 ...<br />

3700<br />

24 ...<br />

14500<br />

330 ...<br />

63000<br />

60 100 36 36 60 36 35 66 60<br />

Torque load<br />

uniform<br />

non uniform<br />

rough – – –<br />

very rough – – – –<br />

Installation and alignment Rigid installation,<br />

well aligned<br />

Rigid installation,<br />

– – – – –<br />

roughly aligned<br />

Flexible installation – – – – –<br />

Torsional stiffness Torsionally rigid – – – – – – –<br />

Torsionally flexible – – – –<br />

Highly flexible – – – – – –<br />

Torque transmission Free of torsional backlash – – – – –<br />

Low torsional backlash – – – – –<br />

Overload withstand<br />

– –<br />

capability<br />

Assembly Plug-in assembly – – –<br />

with Taper clamping bushes – – – –<br />

Maintenance<br />

Wear parts easily<br />

–<br />

dismountable<br />

Maintenance-free – – – – – – –<br />

Low-maintenance - interval<br />

–<br />

1year<br />

Environment ATEX 94/9/EC Approval – – –<br />

Operating temperature<br />

range<br />

-20 ...<br />

+80 °C<br />

-40 ...<br />

+280 °C<br />

-50 ...<br />

+100 °C<br />

-30 ...<br />

+80 °C<br />

-50 ...<br />

+100 °C<br />

-30 ...<br />

+80 °C<br />

-50 ...<br />

+70 °C<br />

-40 ...<br />

+120 °C<br />

Chemically aggressive<br />

Coupling material Cast iron – –<br />

Steel – – –<br />

Stainless steel – – – – – –<br />

Add-on parts / types Adapter –<br />

Brake disk – –<br />

Brake drum – –<br />

Axial backlash limiter – – – –<br />

Shiftgear – – – –<br />

Flange type – –<br />

Flange to SAE J620d – –<br />

1600 ...<br />

90000<br />

-40 ...<br />

+80 °C<br />

(450) 655-7447<br />

info@pt-dstech.com<br />

www.dstech.ca<br />

1275 Newton, local 15<br />

Boucherville, Qc,<br />

Canada, J4B 5H2<br />

<strong>Standard</strong><br />

On request<br />

– Not possible<br />

3/2 Siemens MD 10.1 · 2011