Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

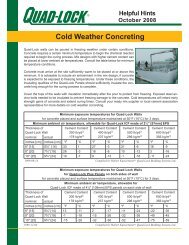

General Hot Weather Concreting Guidelines<br />

• Pour early in the morning to take advantage of cooler ambient temperatures.<br />

• Spray a water mist over forms to help dissapate stored heat.<br />

PRODUCT MANUAL<br />

• Avoid build-up of concrete on hot rebar by vibrating rebar between lifts, or bypassing upper rebar by pouring from<br />

side of wall.<br />

• “Site-mix” concrete that must be transported long distances (or in heavy traffic).<br />

• Keep plasticizer or set-retarder on site for emergencies.<br />

• Order chilled water or ice added to the mix at the batch plant, if available.<br />

• Use placement techniques and slump that will allow the fastest practical placement of concrete.<br />

REINFORCING STEEL (REBAR)<br />

The <strong>Quad</strong>-<strong>Lock</strong> system has been designed to accommodate horizontal reinforcing steel placement in the molded “rebar<br />

chairs” on the <strong>Quad</strong>-<strong>Lock</strong> Ties. The system is ideally suited for even 12" [30cm] increments on the horizontal plane.<br />

Vertical reinforcing steel of almost any spacing can be accommodated in the <strong>Quad</strong>-<strong>Lock</strong> System. The design and<br />

placement of reinforcing steel in the <strong>Quad</strong>-<strong>Lock</strong> System should be in accordance with acceptable reinforced concrete<br />

standards and/or needs to be designed by a professional structural engineer. Some reinforcing steel design guidelines<br />

can be found in Appendix A and prescriptive reinforcing designs can be found in the IRC (USA), the NBC (Canada) and<br />

other national building codes.<br />

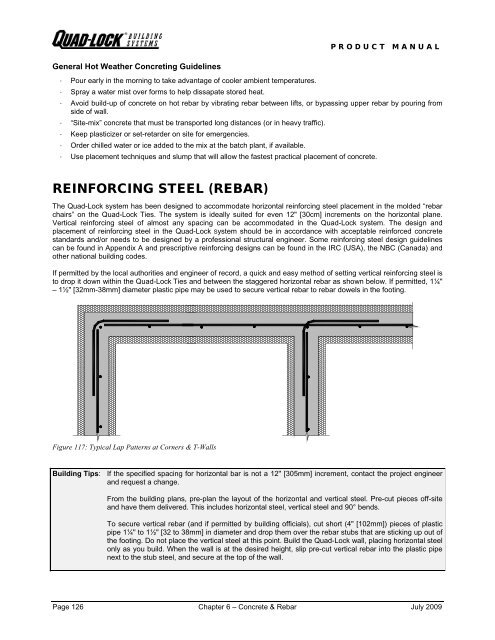

If permitted by the local authorities and engineer of record, a quick and easy method of setting vertical reinforcing steel is<br />

to drop it down within the <strong>Quad</strong>-<strong>Lock</strong> Ties and between the staggered horizontal rebar as shown below. If permitted, 1¼"<br />

– 1½" [32mm-38mm] diameter plastic pipe may be used to secure vertical rebar to rebar dowels in the footing.<br />

Figure 117: Typical Lap Patterns at Corners & T-Walls<br />

<strong>Building</strong> Tips: If the specified spacing for horizontal bar is not a 12" [305mm] increment, contact the project engineer<br />

and request a change.<br />

From the building plans, pre-plan the layout of the horizontal and vertical steel. Pre-cut pieces off-site<br />

and have them delivered. This includes horizontal steel, vertical steel and 90° bends.<br />

To secure vertical rebar (and if permitted by building officials), cut short (4" [102mm]) pieces of plastic<br />

pipe 1¼" to 1½" [32 to 38mm] in diameter and drop them over the rebar stubs that are sticking up out of<br />

the footing. Do not place the vertical steel at this point. Build the <strong>Quad</strong>-<strong>Lock</strong> wall, placing horizontal steel<br />

only as you build. When the wall is at the desired height, slip pre-cut vertical rebar into the plastic pipe<br />

next to the stub steel, and secure at the top of the wall.<br />

Page 126 Chapter 6 – Concrete & Rebar July 2009