Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Properties <strong>of</strong> ductile cast ir<strong>on</strong> pipes<br />

2.2 How the pipes are produced<br />

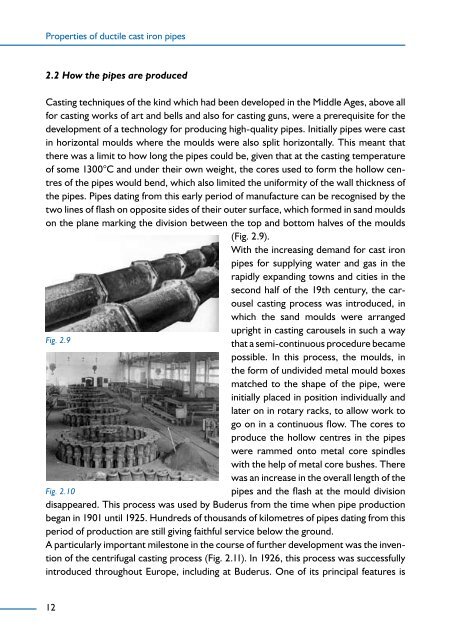

<strong>Cast</strong>ing techniques <strong>of</strong> the kind which had been developed in the Middle Ages, above all<br />

for casting works <strong>of</strong> art and bells and also for casting guns, were a prerequisite for the<br />

development <strong>of</strong> a technology for producing high-quality pipes. Initially pipes were cast<br />

in horiz<strong>on</strong>tal moulds where the moulds were also split horiz<strong>on</strong>tally. This meant that<br />

there was a limit to how l<strong>on</strong>g the pipes could be, given that at the casting temperature<br />

<strong>of</strong> some 1300°C and under their own weight, the cores used to form the hollow centres<br />

<strong>of</strong> the pipes would bend, which also limited the uniformity <strong>of</strong> the wall thickness <strong>of</strong><br />

the pipes. Pipes dating from this early period <strong>of</strong> manufacture can be recognised by the<br />

two lines <strong>of</strong> flash <strong>on</strong> opposite sides <strong>of</strong> their outer surface, which formed in sand moulds<br />

<strong>on</strong> the plane marking the divisi<strong>on</strong> between the top and bottom halves <strong>of</strong> the moulds<br />

(Fig. 2.9).<br />

With the increasing demand for cast ir<strong>on</strong><br />

pipes for supplying water and gas in the<br />

rapidly expanding towns and cities in the<br />

sec<strong>on</strong>d half <strong>of</strong> the 19th century, the carousel<br />

casting process was introduced, in<br />

which the sand moulds were arranged<br />

upright in casting carousels in such a way<br />

Fig. 2.9<br />

that a semi-c<strong>on</strong>tinuous procedure became<br />

possible. In this process, the moulds, in<br />

the form <strong>of</strong> undivided metal mould boxes<br />

matched to the shape <strong>of</strong> the pipe, were<br />

initially placed in positi<strong>on</strong> individually and<br />

later <strong>on</strong> in rotary racks, to allow work to<br />

go <strong>on</strong> in a c<strong>on</strong>tinuous flow. The cores to<br />

produce the hollow centres in the pipes<br />

were rammed <strong>on</strong>to metal core spindles<br />

with the help <strong>of</strong> metal core bushes. There<br />

was an increase in the overall length <strong>of</strong> the<br />

Fig. 2.10<br />

pipes and the flash at the mould divisi<strong>on</strong><br />

disappeared. This process was used by <str<strong>on</strong>g>Buderus</str<strong>on</strong>g> from the time when pipe producti<strong>on</strong><br />

began in 1901 until 192 . Hundreds <strong>of</strong> thousands <strong>of</strong> kilometres <strong>of</strong> pipes dating from this<br />

period <strong>of</strong> producti<strong>on</strong> are still giving faithful service below the ground.<br />

A particularly important milest<strong>on</strong>e in the course <strong>of</strong> further development was the inventi<strong>on</strong><br />

<strong>of</strong> the centrifugal casting process (Fig. 2.11). In 192 , this process was successfully<br />

introduced throughout Europe, including at <str<strong>on</strong>g>Buderus</str<strong>on</strong>g>. One <strong>of</strong> its principal features is<br />

12