Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8.3 Outside protecti<strong>on</strong><br />

Outside protecti<strong>on</strong>, joints, other points<br />

With this technique, the outside protecti<strong>on</strong> <strong>of</strong> the ductile cast ir<strong>on</strong> pipes c<strong>on</strong>sists <strong>of</strong><br />

plastic-modified cement mortar (ZMU) to DIN EN 1 2. The joint area has to be<br />

protected with a shrink-<strong>on</strong> sleeve. Shrink-<strong>on</strong> sleeves <strong>of</strong> tape material should not be used<br />

in this case.<br />

8.4 Joints<br />

Because the pipe for medium is pulled in by steered pilot boring, BLS ® joint also has to<br />

be used in this case. The permitted tractive forces and operating pressures for the BLS ®<br />

joint are shown in Table 2.1 in secti<strong>on</strong> 2. However, due to the oversize, the tractive<br />

forces which can be expected will not be excessively high.<br />

8.5 Other points<br />

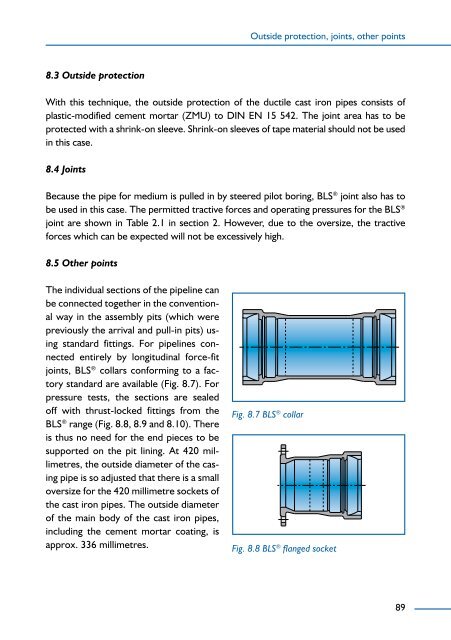

The individual secti<strong>on</strong>s <strong>of</strong> the pipeline can<br />

be c<strong>on</strong>nected together in the c<strong>on</strong>venti<strong>on</strong>al<br />

way in the assembly pits (which were<br />

previously the arrival and pull-in pits) using<br />

standard fittings. For pipelines c<strong>on</strong>nected<br />

entirely by l<strong>on</strong>gitudinal force-fit<br />

joints, BLS ® collars c<strong>on</strong>forming to a factory<br />

standard are available (Fig. 8.7). For<br />

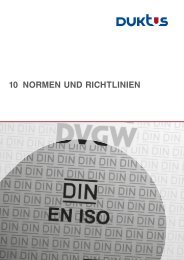

pressure tests, the secti<strong>on</strong>s are sealed<br />

<strong>of</strong>f with thrust-locked fittings from the<br />

BLS ® range (Fig. 8.8, 8.9 and 8.10). There<br />

is thus no need for the end pieces to be<br />

supported <strong>on</strong> the pit lining. At 20 millimetres,<br />

the outside diameter <strong>of</strong> the casing<br />

pipe is so adjusted that there is a small<br />

oversize for the 20 millimetre sockets <strong>of</strong><br />

the cast ir<strong>on</strong> pipes. The outside diameter<br />

<strong>of</strong> the main body <strong>of</strong> the cast ir<strong>on</strong> pipes,<br />

including the cement mortar coating, is<br />

approx. 33 millimetres.<br />

Fig. 8.7 BLS ® collar<br />

Fig. 8.8 BLS ® flanged socket<br />

89