Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Buderus Manual on Trenchless Installation of Ductile Cast ... - Duktus

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Trenchless</strong> replacement <strong>of</strong> gas and water pipelines<br />

3.3 Requirements for the new pipe<br />

The new pipe and its joints have to withstand high tractive forces and still have to have<br />

large safety margins when they do so. The pipe has to have rugged outside protecti<strong>on</strong><br />

because it cannot be guaranteed that there will not be any debris, st<strong>on</strong>es or fragments<br />

in the z<strong>on</strong>e where the pipeline is situated. It is important for the tracti<strong>on</strong> head to be able<br />

to be fitted and removed quickly and straightforwardly when it is being recovered, even<br />

when the weather is very bad. The pipe and its joints have to be l<strong>on</strong>g-lived and resistant<br />

to tree roots. Because the paths followed by many pipelines are not exactly straight, it is<br />

vital for the sockets to be able to accommodate angular deflecti<strong>on</strong>s. In inner-city areas,<br />

launch pits are a maximum <strong>of</strong> 7 metres in length so the ratio between the size <strong>of</strong> the<br />

launch pit and the number <strong>of</strong> joints to be made is very good. Because a combinati<strong>on</strong> <strong>of</strong><br />

trenchless and open-trench techniques is <strong>of</strong>ten used, the types <strong>of</strong> pipe used have to be<br />

compatible and there has to be a complete range <strong>of</strong> fittings available, including for use in<br />

the intermediate pits.<br />

<str<strong>on</strong>g>Buderus</str<strong>on</strong>g> ductile cast ir<strong>on</strong> pipes with cement mortar coatings and BLS ® joints have all<br />

these essential prerequisites. They are thus the ideal pipes for the trenchless replacement<br />

<strong>of</strong> pipelines. What is more, there are fittings for performing leak tests which are very<br />

easy to use and which are easily fitted and removed. The requirements in respect <strong>of</strong><br />

permitted tractive forces, angular deflecti<strong>on</strong>s and minimum radiuses <strong>of</strong> curves which<br />

have to be met under the DVGW rules and the internal rules <strong>of</strong> Berliner Wasserbetriebe<br />

are given in Tables 2.1 and 2.2 in secti<strong>on</strong> 2.<br />

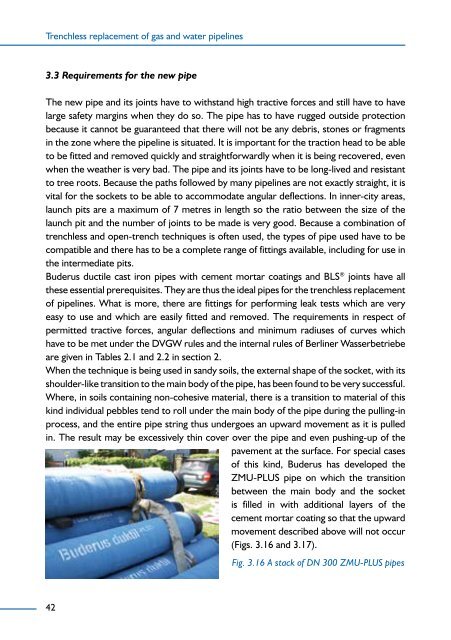

When the technique is being used in sandy soils, the external shape <strong>of</strong> the socket, with its<br />

shoulder-like transiti<strong>on</strong> to the main body <strong>of</strong> the pipe, has been found to be very successful.<br />

Where, in soils c<strong>on</strong>taining n<strong>on</strong>-cohesive material, there is a transiti<strong>on</strong> to material <strong>of</strong> this<br />

kind individual pebbles tend to roll under the main body <strong>of</strong> the pipe during the pulling-in<br />

process, and the entire pipe string thus undergoes an upward movement as it is pulled<br />

in. The result may be excessively thin cover over the pipe and even pushing-up <strong>of</strong> the<br />

pavement at the surface. For special cases<br />

<strong>of</strong> this kind, <str<strong>on</strong>g>Buderus</str<strong>on</strong>g> has developed the<br />

ZMU-PLUS pipe <strong>on</strong> which the transiti<strong>on</strong><br />

between the main body and the socket<br />

is filled in with additi<strong>on</strong>al layers <strong>of</strong> the<br />

cement mortar coating so that the upward<br />

movement described above will not occur<br />

(Figs. 3.1 and 3.17).<br />

2<br />

Fig. 3.16 A stack <strong>of</strong> DN 300 ZMU-PLUS pipes