Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

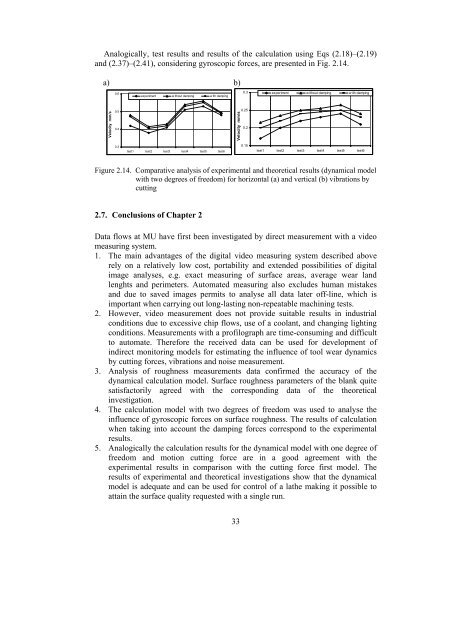

Analogically, test results and results of the calculation us<strong>in</strong>g Eqs (2.18)–(2.19)and (2.37)–(2.41), consider<strong>in</strong>g gyroscopic forces, are presented <strong>in</strong> Fig. 2.14.a) b)0.60.3experiment w ithout damp<strong>in</strong>g with damp<strong>in</strong>gexperiment w ithout damp<strong>in</strong>g w ith damp<strong>in</strong>gVelocity mm/s0.50.4Velocity mm/s0.250.20.3test1 test2 test3 test4 test5 test60.15test1 test2 test3 test4 test5 test6Figure 2.14. Comparative analysis of experimental and theoretical results (dynamical modelwith two degrees of freedom) for horizontal (a) and vertical (b) vibrations bycutt<strong>in</strong>g2.7. Conclusions of Chapter 2Data flows at MU have first been <strong>in</strong>vestigated by direct measurement with a videomeasur<strong>in</strong>g system.1. The ma<strong>in</strong> advantages of the digital video measur<strong>in</strong>g system described aboverely on a relatively low cost, portability and extended possibilities of digitalimage analyses, e.g. exact measur<strong>in</strong>g of surface areas, average wear landlenghts and perimeters. Automated measur<strong>in</strong>g also excludes human mistakesand due to saved images permits to analyse all data later off-l<strong>in</strong>e, which isimportant when carry<strong>in</strong>g out long-last<strong>in</strong>g non-repeatable mach<strong>in</strong><strong>in</strong>g tests.2. However, video measurement does not provide suitable results <strong>in</strong> <strong>in</strong>dustrialconditions due to excessive chip flows, use of a coolant, and chang<strong>in</strong>g light<strong>in</strong>gconditions. Measurements with a profilograph are time-consum<strong>in</strong>g and difficultto automate. Therefore the received data can be used for development of<strong>in</strong>direct monitor<strong>in</strong>g models for estimat<strong>in</strong>g the <strong>in</strong>fluence of tool wear dynamicsby cutt<strong>in</strong>g forces, vibrations and noise measurement.3. Analysis of roughness measurements data confirmed the accuracy of thedynamical calculation model. Surface roughness parameters of the blank quitesatisfactorily agreed with the correspond<strong>in</strong>g data of the theoretical<strong>in</strong>vestigation.4. The calculation model with two degrees of freedom was used to analyse the<strong>in</strong>fluence of gyroscopic forces on surface roughness. The results of calculationwhen tak<strong>in</strong>g <strong>in</strong>to account the damp<strong>in</strong>g forces correspond to the experimentalresults.5. Analogically the calculation results for the dynamical model with one degree offreedom and motion cutt<strong>in</strong>g force are <strong>in</strong> a good agreement with theexperimental results <strong>in</strong> comparison with the cutt<strong>in</strong>g force first model. Theresults of experimental and theoretical <strong>in</strong>vestigations show that the dynamicalmodel is adequate and can be used for control of a lathe mak<strong>in</strong>g it possible toatta<strong>in</strong> the surface quality requested with a s<strong>in</strong>gle run.33