Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

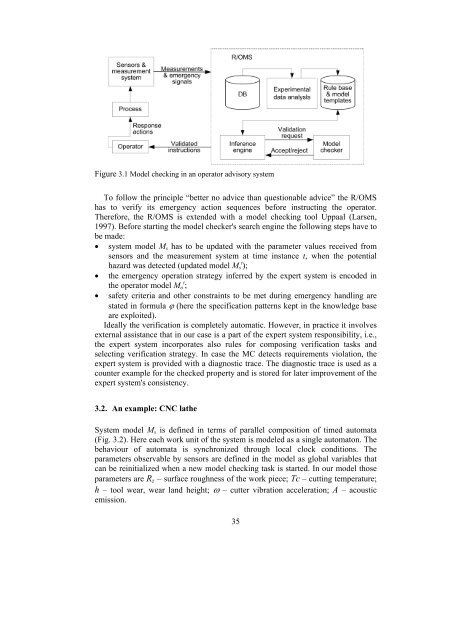

Figure 3.1 Model check<strong>in</strong>g <strong>in</strong> an operator advisory systemTo follow the pr<strong>in</strong>ciple “better no advice than questionable advice” the R/OMShas to verify its emergency action sequences before <strong>in</strong>struct<strong>in</strong>g the operator.Therefore, the R/OMS is extended with a model check<strong>in</strong>g tool Uppaal (Larsen,1997). Before start<strong>in</strong>g the model checker's search eng<strong>in</strong>e the follow<strong>in</strong>g steps have tobe made:• system model M s has to be updated with the parameter values received fromsensors and the measurement system at time <strong>in</strong>stance t, when the potentialhazard was detected (updated model M s t );• the emergency operation strategy <strong>in</strong>ferred by the expert system is encoded <strong>in</strong>the operator model M o t ;• safety criteria and other constra<strong>in</strong>ts to be met dur<strong>in</strong>g emergency handl<strong>in</strong>g arestated <strong>in</strong> formula ϕ (here the specification patterns kept <strong>in</strong> the knowledge baseare exploited).Ideally the verification is completely automatic. However, <strong>in</strong> practice it <strong>in</strong>volvesexternal assistance that <strong>in</strong> our case is a part of the expert system responsibility, i.e.,the expert system <strong>in</strong>corporates also rules for compos<strong>in</strong>g verification tasks andselect<strong>in</strong>g verification strategy. In case the MC detects requirements violation, theexpert system is provided with a diagnostic trace. The diagnostic trace is used as acounter example for the checked property and is stored for later improvement of theexpert system's consistency.3.2. An example: CNC latheSystem model M s is def<strong>in</strong>ed <strong>in</strong> terms of parallel composition of timed automata(Fig. 3.2). Here each work unit of the system is modeled as a s<strong>in</strong>gle automaton. Thebehaviour of automata is synchronized through local clock conditions. Theparameters observable by sensors are def<strong>in</strong>ed <strong>in</strong> the model as global variables thatcan be re<strong>in</strong>itialized when a new model check<strong>in</strong>g task is started. In our model thoseparameters are R z – surface roughness of the work piece; Tc – cutt<strong>in</strong>g temperature;h – tool wear, wear land height; ω – cutter vibration acceleration; A – acousticemission.35