Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

Overview in PDF format - Tallinna Tehnikaülikool

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

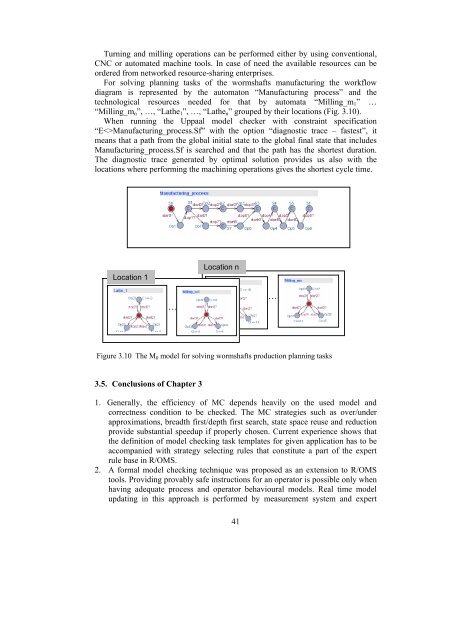

Turn<strong>in</strong>g and mill<strong>in</strong>g operations can be performed either by us<strong>in</strong>g conventional,CNC or automated mach<strong>in</strong>e tools. In case of need the available resources can beordered from networked resource-shar<strong>in</strong>g enterprises.For solv<strong>in</strong>g plann<strong>in</strong>g tasks of the wormshafts manufactur<strong>in</strong>g the workflowdiagram is represented by the automaton “Manufactur<strong>in</strong>g process” and thetechnological resources needed for that by automata “Mill<strong>in</strong>g_m 1 ” …“Mill<strong>in</strong>g_m n ”, …, “Lathe 1 ”, …, “Lathe n ” grouped by their locations (Fig. 3.10).When runn<strong>in</strong>g the Uppaal model checker with constra<strong>in</strong>t specification“EManufactur<strong>in</strong>g_process.Sf” with the option “diagnostic trace – fastest”, itmeans that a path from the global <strong>in</strong>itial state to the global f<strong>in</strong>al state that <strong>in</strong>cludesManufactur<strong>in</strong>g_process.Sf is searched and that the path has the shortest duration.The diagnostic trace generated by optimal solution provides us also with thelocations where perform<strong>in</strong>g the mach<strong>in</strong><strong>in</strong>g operations gives the shortest cycle time.Location 1Location n……Figure 3.10 The M 0 model for solv<strong>in</strong>g wormshafts production plann<strong>in</strong>g tasks3.5. Conclusions of Chapter 31. Generally, the efficiency of MC depends heavily on the used model andcorrectness condition to be checked. The MC strategies such as over/underapproximations, breadth first/depth first search, state space reuse and reductionprovide substantial speedup if properly chosen. Current experience shows thatthe def<strong>in</strong>ition of model check<strong>in</strong>g task templates for given application has to beaccompanied with strategy select<strong>in</strong>g rules that constitute a part of the expertrule base <strong>in</strong> R/OMS.2. A formal model check<strong>in</strong>g technique was proposed as an extension to R/OMStools. Provid<strong>in</strong>g provably safe <strong>in</strong>structions for an operator is possible only whenhav<strong>in</strong>g adequate process and operator behavioural models. Real time modelupdat<strong>in</strong>g <strong>in</strong> this approach is performed by measurement system and expert41