LATVIA UNIVERSITY OF AGRICULTURE - Latvijas ...

LATVIA UNIVERSITY OF AGRICULTURE - Latvijas ...

LATVIA UNIVERSITY OF AGRICULTURE - Latvijas ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

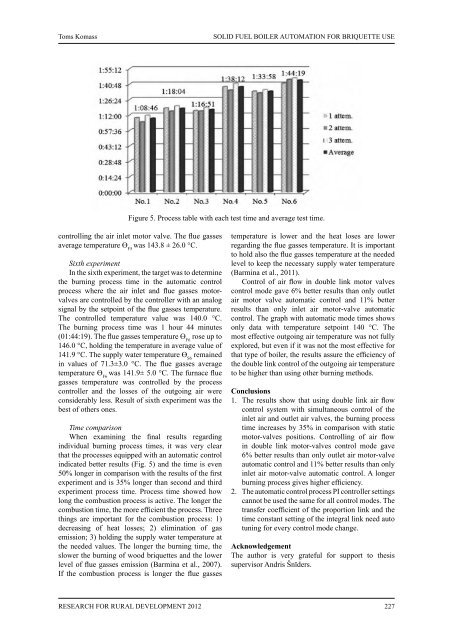

Toms KomassSOLID FUEL BOILER AUTOMATION FOR BRIQUETTE USEFigure 5. Process table with each test time and average test time.controlling the air inlet motor valve. The flue gassesaverage temperature Ө F5was 143.8 ± 26.0 °C.Sixth experimentIn the sixth experiment, the target was to determinethe burning process time in the automatic controlprocess where the air inlet and flue gasses motorvalvesare controlled by the controller with an analogsignal by the setpoint of the flue gasses temperature.The controlled temperature value was 140.0 °C.The burning process time was 1 hour 44 minutes(01:44:19). The flue gasses temperature Ө F6rose up to146.0 °C, holding the temperature in average value of141.9 °C. The supply water temperature Ө S6remainedin values of 71.3±3.0 °C. The flue gasses averagetemperature Ө F6was 141.9± 5.0 °C. The furnace fluegasses temperature was controlled by the processcontroller and the losses of the outgoing air wereconsiderably less. Result of sixth experiment was thebest of others ones.Time comparisonWhen examining the final results regardingindividual burning process times, it was very clearthat the processes equipped with an automatic controlindicated better results (Fig. 5) and the time is even50% longer in comparison with the results of the firstexperiment and is 35% longer than second and thirdexperiment process time. Process time showed howlong the combustion process is active. The longer thecombustion time, the more efficient the process. Threethings are important for the combustion process: 1)decreasing of heat losses; 2) elimination of gasemission; 3) holding the supply water temperature atthe needed values. The longer the burning time, theslower the burning of wood briquettes and the lowerlevel of flue gasses emission (Barmina et al., 2007).If the combustion process is longer the flue gassestemperature is lower and the heat loses are lowerregarding the flue gasses temperature. It is importantto hold also the flue gasses temperature at the neededlevel to keep the necessary supply water temperature(Barmina et al., 2011).Control of air flow in double link motor valvescontrol mode gave 6% better results than only outletair motor valve automatic control and 11% betterresults than only inlet air motor-valve automaticcontrol. The graph with automatic mode times showsonly data with temperature setpoint 140 °C. Themost effective outgoing air temperature was not fullyexplored, but even if it was not the most effective forthat type of boiler, the results assure the efficiency ofthe double link control of the outgoing air temperatureto be higher than using other burning methods.Conclusions1. The results show that using double link air flowcontrol system with simultaneous control of theinlet air and outlet air valves, the burning processtime increases by 35% in comparison with staticmotor-valves positions. Controlling of air flowin double link motor-valves control mode gave6% better results than only outlet air motor-valveautomatic control and 11% better results than onlyinlet air motor-valve automatic control. A longerburning process gives higher efficiency.2. The automatic control process PI controller settingscannot be used the same for all control modes. Thetransfer coefficient of the proportion link and thetime constant setting of the integral link need autotuning for every control mode change.AcknowledgementThe author is very grateful for support to thesissupervisor Andris Šnīders.Research for Rural Development 2012227