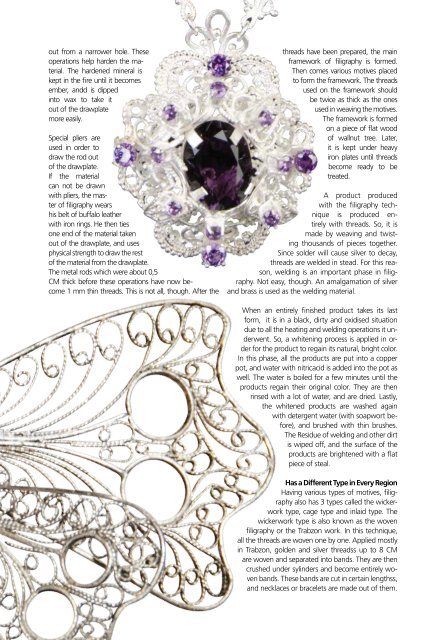

out from a narrower hole. Theseoperations help harden the material.The hardened mineral iskept in the fire until it becomesember, andd is dippedinto wax to take itout of the drawplatemore easily.Special pliers areused in order todraw the rod outof the drawplate.If the materialcan not be drawnwith pliers, the masterof filigraphy wearshis belt of buffalo leatherwith iron rings. He then tiesone end of the material takenout of the drawplate, and usesphysical strength to draw the restof the material from the drawplate.The metal rods which were about 0,5CM thick before these operations have now become1 mm thin threads. This is not all, though. After thethreads have been prepared, the mainframework of filigraphy is formed.Then comes various motives placedto form the framework. The threadsused on the framework shouldbe twice as thick as the onesused in weaving the motives.The framework is formedon a piece of flat woodof wallnut tree. Later,it is kept under heavyiron plates until threadsbecome ready to betreated.A product producedwith the filigraphy techniqueis produced entirelywith threads. So, it ismade by weaving and twistingthousands of pieces together.Since solder will cause silver to decay,threads are welded in stead. For this reason,welding is an important phase in filigraphy.Not easy, though. An amalgamation of silverand brass is used as the welding material.When an entirely finished product takes its lastform, it is in a black, dirty and oxidised situationdue to all the heating and welding operations it underwent.So, a whitening process is applied in orderfor the product to regain its natural, bright color.In this phase, all the products are put into a copperpot, and water with nitricacid is added into the pot aswell. The water is boiled for a few minutes until theproducts regain their original color. They are thenrinsed with a lot of water, and are dried. Lastly,the whitened products are washed againwith detergent water (with soapwort before),and brushed with thin brushes.The Residue of welding and other dirtis wiped off, and the surface of theproducts are brightened with a flatpiece of steal.Has a Different Type in Every RegionHaving various types of motives, filigraphyalso has 3 types called the wickerworktype, cage type and inlaid type. Thewickerwork type is also known as the wovenfiligraphy or the Trabzon work. In this technique,all the threads are woven one by one. Applied mostlyin Trabzon, golden and silver threadss up to 8 CMare woven and separated into bands. They are thencrushed under sylinders and become entirely wovenbands. These bands are cut in certain lengthss,and necklaces or bracelets are made out of them.

In inlaid filigraphy, on the other hand,threads are placed into hollowed surfacesof semiprecious or preciousstones, metal or wooden surfaces.The shape drawn on the surfacewhere the inlaying technique willbe applied is hollowed by engravingor acid. Mostly edged piecesof thread placed into this shapeis embedded into the surface bybeating and crushing with a hammer.The parts that are surpluss areremoved, filed, whitened and brightened.Handgrips, knife, umbrella, cane and spoonhandles, envelope openers, writing utensils,prayer beeds, mouthpieces, clogs and candle holdersare decorated with this technique.In the cage technique, after the threads are shaped, theyare joined together and welded on a framework. Theframework is filled with thinner threads, and the weldingoperation is repeated. If necessary, the product is decoratedwith tiny circles. Ashtrays, lighter cases, cigarette and jewelleryboxes, candle holders, trays, sugar bowls, mouthpieces,waterpipe mouthpieces, flowers, vases, tobacco boxes, cup,glass or jug holders, lampshades, various plates, buttons,cufflinks, ear rings, huts, necklaces, brooches, bracelets,belts and rings are usually produced with this technique.The Filigraphy Training in ISMEKFiligraphy, which has an important placeamong our traditional arts is also within thetraining range of ISMEK, which aims toconvey our traditional values to next generations.Fatma Fisunoglu, the headteacher of the Jewellery designingSilver Filigraphy and Silver Weavingteam, states that the filigraphytraining in ISMEK is twice aweek, consisting of 120 sessionsin total. Adding that female studentsare more interested in thetrainings, Mrs. Fisunoglu also statesthat some male students have showninterest in the trainings recently as well.As far as what we learn from Mrs. Fisunoglu, those whograduate from the Jewellery Technology departmentsalso receive training to improve themselves. We ask Mrs.Fisunoglu how long it takes to be a good master of filigraphy.Stating that hand skill and talent is important infiligraphy as in all our traditional arts, Mrs. Fisunoglu saysthat at least a 2-year period training is required in orderfor the trainee to have some knowledge on the art.Within the training curriculum of the filigraphy trainingin ISMEK given in 4 different course centres in the Anatolianand the European sides are amalgamation metalsand chemicals, semiprocessed products, welding in jewellery,filigraphy, ordering forms in jewellery, and deliveryof jewelleries to customers.

- Page 1: Art Leads Oneto Eternity!

- Page 4 and 5: In ThisEdition1506The StringentMast

- Page 6: Dear Istanbulians,After the industr

- Page 10 and 11: One Marbler Has Carried This Colorf

- Page 12 and 13: this art”. Being single those day

- Page 14 and 15: in flower marbling.” He says, and

- Page 16 and 17: Cicek Derman: The DoyenneFlower of

- Page 18 and 19: and does not want her to either stu

- Page 20 and 21: der the very inside of you.” She

- Page 22 and 23: ate” at all. The creator is one,

- Page 25 and 26: Kundekâri:The Time Defying Heritag

- Page 27: Cracks and incisions which could oc

- Page 30 and 31: land to understand weather he can p

- Page 32 and 33: When Deep WavesWash Ashore!by A. Ul

- Page 34 and 35: 'Bismillah' by Omer Faruk Deretaste

- Page 36 and 37: 'The Asr Surah' by Mustafa Cemil Ef

- Page 38 and 39: Van Gogh,The Genious Painter of Yel

- Page 40 and 41: and anxieties that surrounded him s

- Page 42 and 43: The most prominent features which w

- Page 44 and 45: Starry Night Over the Rhonehe opted

- Page 46 and 47: the left side of his face is a colo

- Page 48 and 49: The Threaded Version of Silver isRe

- Page 52 and 53: Sumi-e: The Elegance which Comesint

- Page 54 and 55: traditions, perform this art seated

- Page 56 and 57: sumed in half an hour after it is p

- Page 59 and 60: er in ISMEK, after her illumination

- Page 61 and 62: 59Illustration: Hatice Ozturk

- Page 63 and 64: there was a captures chamberlain. 5

- Page 65 and 66: lack sides. As far as I can see del

- Page 67 and 68: One of the founders of the civilisa

- Page 69 and 70: The miniature by Ochiai Yoshiiku da

- Page 71 and 72: Miniatures are in the Irony of West

- Page 73 and 74: pictions of various countries, coul

- Page 75 and 76: A miniature example from the work n

- Page 77 and 78: “Ve mâ rameyte iz rameyte ve lak

- Page 79 and 80: usually there is a part consisting

- Page 81 and 82: When applied on wood, Edirnekâri c

- Page 83 and 84: What is very distinct regardingthe

- Page 85 and 86: The ceiling decorations, corner cab

- Page 87 and 88: There is an epigram for the Artof C

- Page 89 and 90: If the paper had spoken and told wh

- Page 91 and 92: nailing, gluing or compressing of t

- Page 93 and 94: gold. The notebooks with gold leave

- Page 95 and 96: laminary and get the required thick

- Page 97 and 98: Both the insufficience of green fie

- Page 100 and 101:

15 years ago, Mr. Yesilce allocated

- Page 102 and 103:

On the Zoomorphic1Originsof the Rum

- Page 104 and 105:

Shape-6Shape-13another finding foun

- Page 106 and 107:

The Harem in the Topkapi Palace,The

- Page 108 and 109:

very much like the school of boys i

- Page 110 and 111:

The Blue Doors of TunisiaThe Articl

- Page 112 and 113:

Tunisia is the pearl of the Mediter

- Page 114 and 115:

Ottoman CultureProducts from Qadi R

- Page 116 and 117:

An Overview of Written Sourcesin Ot

- Page 118 and 119:

Signature of Abdulhamit II on the c

- Page 120 and 121:

Pieces of Wastepapers TurnInto Jewe

- Page 122 and 123:

in a short time, we ask him to make

- Page 124 and 125:

Symbols of theLife of Thoughtby Pro

- Page 126 and 127:

The Gulpayegan Masjid Kufi writing

- Page 128 and 129:

which show some of the monumental w

- Page 130 and 131:

An appearance from the interior of

- Page 132 and 133:

The Kufic script at the top is prep

- Page 134 and 135:

in yerinize grafologla konusuverir.

- Page 136 and 137:

considered as a hard science rather

- Page 138 and 139:

Zeynep Bornovali states that differ

- Page 140 and 141:

The Dance of the Needle with Cerami

- Page 142 and 143:

was not the case, however, for the

- Page 144 and 145:

an area determined on the material

- Page 146 and 147:

Dilek Hanif: A Fashion DesignerWho

- Page 148 and 149:

others prefer to have a single and

- Page 150 and 151:

Princess Nazli:The Patron of Arts a

- Page 152 and 153:

which was also known as “Villa He

- Page 154 and 155:

A Bouquet From the Hidden Paradiseb

- Page 156 and 157:

Canfeza (Heart touching) A fully st

- Page 158 and 159:

“Someone whom I hadn’t met befo

- Page 160 and 161:

The Storm of ISMEK Blowingin the In

- Page 162:

Menaf Nam's work which was awarded