Sustainability Report - Dell

Sustainability Report - Dell

Sustainability Report - Dell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

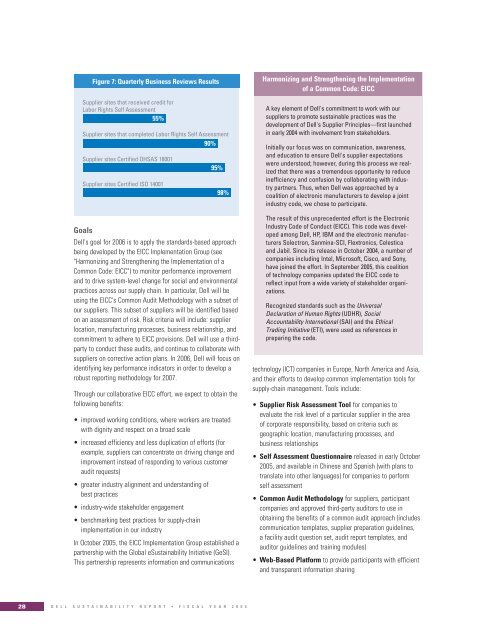

GoalsFigure 7: Quarterly Business Reviews ResultsSupplier sites that received credit forLabor Rights Self Assessment55%Supplier sites that completed Labor Rights Self Assessment90%Supplier sites Certified OHSAS 18001Supplier sites Certified ISO 1400195%98%<strong>Dell</strong>'s goal for 2006 is to apply the standards-based approachbeing developed by the EICC Implementation Group (see"Harmonizing and Strengthening the Implementation of aCommon Code: EICC") to monitor performance improvementand to drive system-level change for social and environmentalpractices across our supply chain. In particular, <strong>Dell</strong> will beusing the EICC's Common Audit Methodology with a subset ofour suppliers. This subset of suppliers will be identified basedon an assessment of risk. Risk criteria will include: supplierlocation, manufacturing processes, business relationship, andcommitment to adhere to EICC provisions. <strong>Dell</strong> will use a thirdpartyto conduct these audits, and continue to collaborate withsuppliers on corrective action plans. In 2006, <strong>Dell</strong> will focus onidentifying key performance indicators in order to develop arobust reporting methodology for 2007.Through our collaborative EICC effort, we expect to obtain thefollowing benefits:• improved working conditions, where workers are treatedwith dignity and respect on a broad scale• increased efficiency and less duplication of efforts (forexample, suppliers can concentrate on driving change andimprovement instead of responding to various customeraudit requests)• greater industry alignment and understanding ofbest practices• industry-wide stakeholder engagement• benchmarking best practices for supply-chainimplementation in our industryIn October 2005, the EICC Implementation Group established apartnership with the Global e<strong>Sustainability</strong> Initiative (GeSI).This partnership represents information and communicationsHarmonizing and Strengthening the Implementationof a Common Code: EICCA key element of <strong>Dell</strong>'s commitment to work with oursuppliers to promote sustainable practices was thedevelopment of <strong>Dell</strong>'s Supplier Principles—first launchedin early 2004 with involvement from stakeholders.Initially our focus was on communication, awareness,and education to ensure <strong>Dell</strong>'s supplier expectationswere understood; however, during this process we realizedthat there was a tremendous opportunity to reduceinefficiency and confusion by collaborating with industrypartners. Thus, when <strong>Dell</strong> was approached by acoalition of electronic manufacturers to develop a jointindustry code, we chose to participate.The result of this unprecedented effort is the ElectronicIndustry Code of Conduct (EICC). This code was developedamong <strong>Dell</strong>, HP, IBM and the electronic manufacturersSolectron, Sanmina-SCI, Flextronics, Celesticaand Jabil. Since its release in October 2004, a number ofcompanies including Intel, Microsoft, Cisco, and Sony,have joined the effort. In September 2005, this coalitionof technology companies updated the EICC code toreflect input from a wide variety of stakeholder organizations.Recognized standards such as the UniversalDeclaration of Human Rights (UDHR), SocialAccountability International (SAI) and the EthicalTrading Initiative (ETI), were used as references inpreparing the code.technology (ICT) companies in Europe, North America and Asia,and their efforts to develop common implementation tools forsupply-chain management. Tools include:• Supplier Risk Assessment Tool for companies toevaluate the risk level of a particular supplier in the areaof corporate responsibility, based on criteria such asgeographic location, manufacturing processes, andbusiness relationships• Self Assessment Questionnaire released in early October2005, and available in Chinese and Spanish (with plans totranslate into other languages) for companies to performself assessment• Common Audit Methodology for suppliers, participantcompanies and approved third-party auditors to use inobtaining the benefits of a common audit approach (includescommunication templates, supplier preparation guidelines,a facility audit question set, audit report templates, andauditor guidelines and training modules)• Web-Based Platform to provide participants with efficientand transparent information sharing28 D E L L S U S T A I N A B I L I T Y R E P O R T • F I S C A L Y E A R 2 0 0 6