Sustainability Report - Dell

Sustainability Report - Dell

Sustainability Report - Dell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

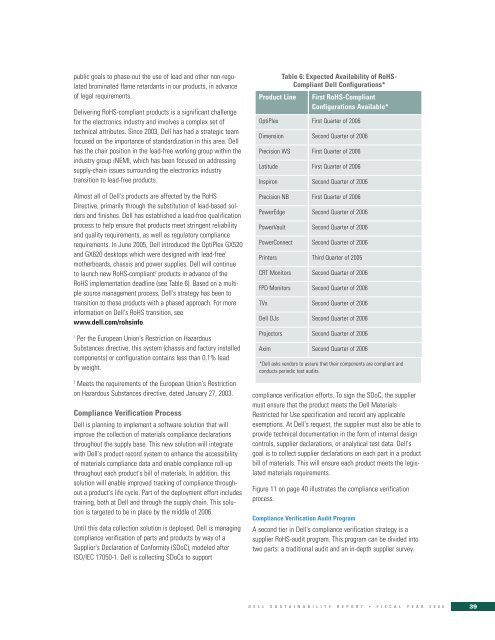

public goals to phase-out the use of lead and other non-regulatedbrominated flame retardants in our products, in advanceof legal requirements.Delivering RoHS-compliant products is a significant challengefor the electronics industry and involves a complex set oftechnical attributes. Since 2003, <strong>Dell</strong> has had a strategic teamfocused on the importance of standardization in this area. <strong>Dell</strong>has the chair position in the lead-free working group within theindustry group iNEMI, which has been focused on addressingsupply-chain issues surrounding the electronics industrytransition to lead-free products.Almost all of <strong>Dell</strong>'s products are affected by the RoHSDirective, primarily through the substitution of lead-based soldersand finishes. <strong>Dell</strong> has established a lead-free qualificationprocess to help ensure that products meet stringent reliabilityand quality requirements, as well as regulatory compliancerequirements. In June 2005, <strong>Dell</strong> introduced the OptiPlex GX520and GX620 desktops which were designed with lead-free 1motherboards, chassis and power supplies. <strong>Dell</strong> will continueto launch new RoHS-compliant 2 products in advance of theRoHS implementation deadline (see Table 6). Based on a multiplesource management process, <strong>Dell</strong>'s strategy has been totransition to these products with a phased approach. For moreinformation on <strong>Dell</strong>'s RoHS transition, seewww.dell.com/rohsinfo.1Per the European Union's Restriction on HazardousSubstances directive, this system (chassis and factory installedcomponents) or configuration contains less than 0.1% leadby weight.2Meets the requirements of the European Union's Restrictionon Hazardous Substances directive, dated January 27, 2003.Compliance Verification Process<strong>Dell</strong> is planning to implement a software solution that willimprove the collection of materials compliance declarationsthroughout the supply base. This new solution will integratewith <strong>Dell</strong>'s product record system to enhance the accessibilityof materials compliance data and enable compliance roll-upthroughout each product's bill of materials. In addition, thissolution will enable improved tracking of compliance throughouta product's life cycle. Part of the deployment effort includestraining, both at <strong>Dell</strong> and through the supply chain. This solutionis targeted to be in place by the middle of 2006.Until this data collection solution is deployed, <strong>Dell</strong> is managingcompliance verification of parts and products by way of aSupplier's Declaration of Conformity (SDoC), modeled afterISO/IEC 17050-1. <strong>Dell</strong> is collecting SDoCs to supportTable 6: Expected Availability of RoHS-Compliant <strong>Dell</strong> Configurations*Product Line First RoHS-CompliantConfigurations Available*OptiPlex First Quarter of 2006Dimension Second Quarter of 2006Precision WS First Quarter of 2006Latitude First Quarter of 2006Inspiron Second Quarter of 2006Precision NB First Quarter of 2006PowerEdge Second Quarter of 2006PowerVault Second Quarter of 2006PowerConnect Second Quarter of 2006Printers Third Quarter of 2005CRT Monitors Second Quarter of 2006FPD Monitors Second Quarter of 2006TVs Second Quarter of 2006<strong>Dell</strong> DJs Second Quarter of 2006Projectors Second Quarter of 2006Axim Second Quarter of 2006*<strong>Dell</strong> asks vendors to assure that their components are compliant andconducts periodic test audits.compliance verification efforts. To sign the SDoC, the suppliermust ensure that the product meets the <strong>Dell</strong> MaterialsRestricted for Use specification and record any applicableexemptions. At <strong>Dell</strong>'s request, the supplier must also be able toprovide technical documentation in the form of internal designcontrols, supplier declarations, or analytical test data. <strong>Dell</strong>'sgoal is to collect supplier declarations on each part in a productbill of materials. This will ensure each product meets the legislatedmaterials requirements.Figure 11 on page 40 illustrates the compliance verificationprocess.Compliance Verification Audit ProgramA second tier in <strong>Dell</strong>'s compliance verification strategy is asupplier RoHS-audit program. This program can be divided intotwo parts: a traditional audit and an in-depth supplier survey.D E L L S U S T A I N A B I L I T Y R E P O R T • F I S C A L Y E A R 2 0 0 639