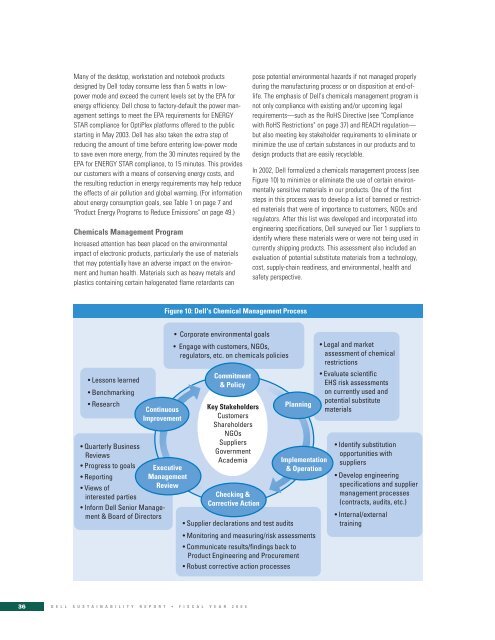

Many of the desktop, workstation and notebook productsdesigned by <strong>Dell</strong> today consume less than 5 watts in lowpowermode and exceed the current levels set by the EPA forenergy efficiency. <strong>Dell</strong> chose to factory-default the power managementsettings to meet the EPA requirements for ENERGYSTAR compliance for OptiPlex platforms offered to the publicstarting in May 2003. <strong>Dell</strong> has also taken the extra step ofreducing the amount of time before entering low-power modeto save even more energy, from the 30 minutes required by theEPA for ENERGY STAR compliance, to 15 minutes. This providesour customers with a means of conserving energy costs, andthe resulting reduction in energy requirements may help reducethe effects of air pollution and global warming. (For informationabout energy consumption goals, see Table 1 on page 7 and"Product Energy Programs to Reduce Emissions" on page 49.)Chemicals Management ProgramIncreased attention has been placed on the environmentalimpact of electronic products, particularly the use of materialsthat may potentially have an adverse impact on the environmentand human health. Materials such as heavy metals andplastics containing certain halogenated flame retardants canpose potential environmental hazards if not managed properlyduring the manufacturing process or on disposition at end-oflife.The emphasis of <strong>Dell</strong>'s chemicals management program isnot only compliance with existing and/or upcoming legalrequirements—such as the RoHS Directive (see "Compliancewith RoHS Restrictions" on page 37) and REACH regulation—but also meeting key stakeholder requirements to eliminate orminimize the use of certain substances in our products and todesign products that are easily recyclable.In 2002, <strong>Dell</strong> formalized a chemicals management process (seeFigure 10) to minimize or eliminate the use of certain environmentallysensitive materials in our products. One of the firststeps in this process was to develop a list of banned or restrictedmaterials that were of importance to customers, NGOs andregulators. After this list was developed and incorporated intoengineering specifications, <strong>Dell</strong> surveyed our Tier 1 suppliers toidentify where these materials were or were not being used incurrently shipping products. This assessment also included anevaluation of potential substitute materials from a technology,cost, supply-chain readiness, and environmental, health andsafety perspective.Figure 10: <strong>Dell</strong>'s Chemical Management Process• Lessons learned• Benchmarking• Research• Quarterly BusinessReviews• Progress to goals• <strong>Report</strong>ing• Views ofinterested partiesContinuousImprovement• Inform <strong>Dell</strong> Senior Management& Board of DirectorsExecutiveManagementReview• Corporate environmental goals• Engage with customers, NGOs,regulators, etc. on chemicals policiesCommitment& PolicyKey StakeholdersCustomersShareholdersNGOsSuppliersGovernmentAcademiaChecking &Corrective ActionPlanningImplementation& Operation• Supplier declarations and test audits• Monitoring and measuring/risk assessments• Communicate results/findings back toProduct Engineering and Procurement• Robust corrective action processes• Legal and marketassessment of chemicalrestrictions• Evaluate scientificEHS risk assessmentson currently used andpotential substitutematerials• Identify substitutionopportunities withsuppliers• Develop engineeringspecifications and suppliermanagement processes(contracts, audits, etc.)• Internal/externaltraining36 D E L L S U S T A I N A B I L I T Y R E P O R T • F I S C A L Y E A R 2 0 0 6

Based on the Tier 1 supply chain information, in 2003 <strong>Dell</strong>established corporate chemicals management goals with aparticular focus on lead and bromine reduction (see Table 1on page 7). Striving to meet these goals, as well as a continuedfocus on meeting the growing number of legislative, marketand stakeholder-driven chemical restrictions, led to anincreased focus on ensuring that restricted substances werenot selected in product design or being used by suppliers.Internal and external training was conducted not only to ensurethat both <strong>Dell</strong> and supplier engineering and procurement representativeswere informed of which substances were restrictedfor use in <strong>Dell</strong> products, but also to encourage development ofalternative materials and technologies that could be selected infuture product generations.Process controls such as piece-part supplier declarations, <strong>Dell</strong>factory and supplier material testing audits, and correctiveaction processes were implemented to ensure that <strong>Dell</strong>'s chemicalsmanagement objectives were met throughout the organizationand into the supply chain. Through this integrated managementprocess, <strong>Dell</strong> has proactively established a workingmodel that can be used to make more informed decisions whennew scientific findings call for alternative material selections.This model will also be used to efficiently manage any futuresubstance restrictions through robust internal and externaldesign controls.Currently, more than 50 substances and compounds arerestricted for use in the manufacture of <strong>Dell</strong> products and inthe finished products themselves (see "Restricted Substances").Compliance with RoHS RestrictionsGlobal concerns over the human health and environmental risksassociated with the use of certain environmentally-sensitivematerials in electronic products has led the European Union(E.U.) to enact the European Union's Restriction on HazardousSubstances directive (RoHS), designed to restrict the use ofcadmium, hexavalent chromium, lead, mercury and certainhalogenated flame retardants (PBBs and PBDEs) in electronicproducts. This directive will be implemented in the EuropeanUnion on July 1, 2006. Similar legislation is also pending inChina and various states in the United States. <strong>Dell</strong>'s goal isto comply with the RoHS Directive requirements prior to theJuly 1, 2006 E.U. implementation deadline and continue toincorporate these changes in our global product lines.<strong>Dell</strong> understands the environmental risks associated withthe substances covered by the RoHS Directive and is committedto eliminating the use of these, as well as other environmentally-sensitivesubstances, in our products. Through ourintegrated Restricted Materials Program, <strong>Dell</strong> has prohibitedthe use of cadmium, hexavalent chromium, mercury, PBBsand PBDEs in <strong>Dell</strong> branded products. <strong>Dell</strong> has also establishedRestricted Substances (certain exemptions may apply)• Asbestos and its compounds• Azo dyes and colorants• Cadmium and its compounds• Chlorofluorocarbons (CFCs)• Chloroparaffins, short-chained (10-13 carbon chain)• Chromium VI and its compounds• Brominated/chlorinated flame retardants in desktop, notebookand server chassis plastic parts• Hydrochlorofluorocarbons (HCFCs)• Lead and its compounds• Mercury and its compounds• Nickel and its compounds• Polybrominated biphenyls (PBBs) and their ethers andoxides (PBDEs and PBBEs), including deca-BDE• Polychlorinated biphenyls (PCBs) and terphenyls (PCTs)• Polychlorinated naphthalene (PCN)• Polyvinyl chloride (PVC)• Tributyl tin (TBT) and Triphenyl tin (TPT) compoundsIn addition to the restricted substances, in mid-2006, <strong>Dell</strong>will begin collecting information from suppliers on the useand non-use of the following substances:• Antimony and its compounds• Arsenic and its compounds• Beryllium and its compounds• Bismuth and its compounds• Brominated/chlorinated flame retardants used in anyapplication• Certain phthalates• Selenium and its compoundsD E L L S U S T A I N A B I L I T Y R E P O R T • F I S C A L Y E A R 2 0 0 637