Sustainability Report - Dell

Sustainability Report - Dell

Sustainability Report - Dell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

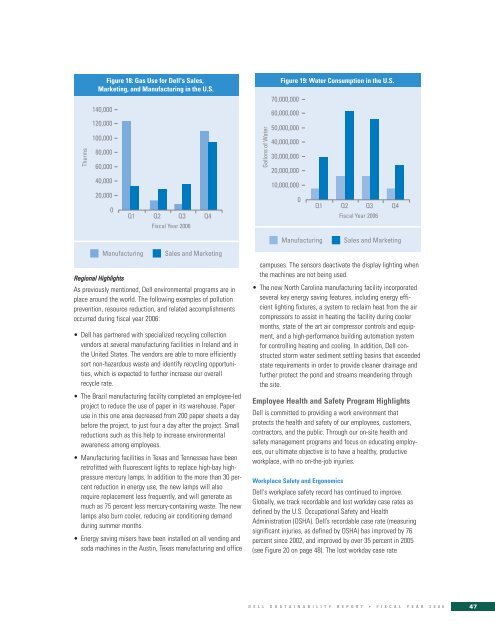

ThermsFigure 18: Gas Use for <strong>Dell</strong>'s Sales,Marketing, and Manufacturing in the U.S.140,000120,000100,00080,00060,00040,00020,0000Q1 Q2 Q3Fiscal Year 2006Q4Gallons of WaterFigure 19: Water Consumption in the U.S.70,000,00060,000,00050,000,00040,000,00030,000,00020,000,00010,000,0000Q1 Q2 Q3 Q4Fiscal Year 2006ManufacturingRegional HighlightsSales and MarketingAs previously mentioned, <strong>Dell</strong> environmental programs are inplace around the world. The following examples of pollutionprevention, resource reduction, and related accomplishmentsoccurred during fiscal year 2006:• <strong>Dell</strong> has partnered with specialized recycling collectionvendors at several manufacturing facilities in Ireland and inthe United States. The vendors are able to more efficientlysort non-hazardous waste and identify recycling opportunities,which is expected to further increase our overallrecycle rate.• The Brazil manufacturing facility completed an employee-ledproject to reduce the use of paper in its warehouse. Paperuse in this one area decreased from 200 paper sheets a daybefore the project, to just four a day after the project. Smallreductions such as this help to increase environmentalawareness among employees.• Manufacturing facilities in Texas and Tennessee have beenretrofitted with fluorescent lights to replace high-bay highpressuremercury lamps. In addition to the more than 30 percentreduction in energy use, the new lamps will alsorequire replacement less frequently, and will generate asmuch as 75 percent less mercury-containing waste. The newlamps also burn cooler, reducing air conditioning demandduring summer months.• Energy saving misers have been installed on all vending andsoda machines in the Austin, Texas manufacturing and officeManufacturingSales and Marketingcampuses. The sensors deactivate the display lighting whenthe machines are not being used.• The new North Carolina manufacturing facility incorporatedseveral key energy saving features, including energy efficientlighting fixtures, a system to reclaim heat from the aircompressors to assist in heating the facility during coolermonths, state of the art air compressor controls and equipment,and a high-performance building automation systemfor controlling heating and cooling. In addition, <strong>Dell</strong> constructedstorm water sediment settling basins that exceededstate requirements in order to provide cleaner drainage andfurther protect the pond and streams meandering throughthe site.Employee Health and Safety Program Highlights<strong>Dell</strong> is committed to providing a work environment thatprotects the health and safety of our employees, customers,contractors, and the public. Through our on-site health andsafety management programs and focus on educating employees,our ultimate objective is to have a healthy, productiveworkplace, with no on-the-job injuries.Workplace Safety and Ergonomics<strong>Dell</strong>'s workplace safety record has continued to improve.Globally, we track recordable and lost workday case rates asdefined by the U.S. Occupational Safety and HealthAdministration (OSHA). <strong>Dell</strong>’s recordable case rate (measuringsignificant injuries, as defined by OSHA) has improved by 76percent since 2002, and improved by over 35 percent in 2005(see Figure 20 on page 48). The lost workday case rateD E L L S U S T A I N A B I L I T Y R E P O R T • F I S C A L Y E A R 2 0 0 647