Mobrey

Mobrey

Mobrey

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

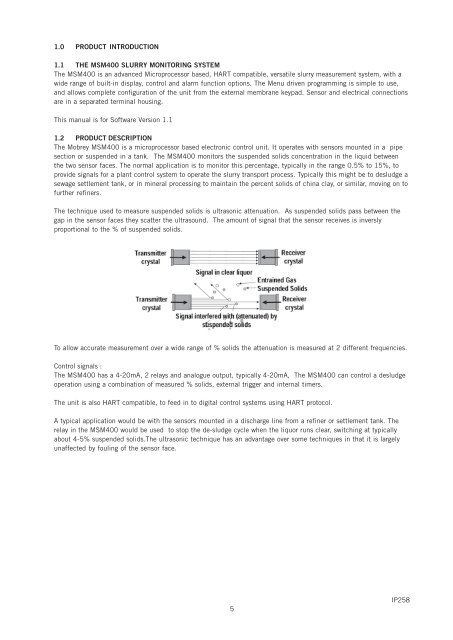

1.0 PRODUCT INTRODUCTION1.1 THE MSM400 SLURRY MONITORING SYSTEMThe MSM400 is an advanced Microprocessor based, HART compatible, versatile slurry measurement system, with awide range of built-in display, control and alarm function options. The Menu driven programming is simple to use,and allows complete configuration of the unit from the external membrane keypad. Sensor and electrical connectionsare in a separated terminal housing.This manual is for Software Version 1.11.2 PRODUCT DESCRIPTIONThe <strong>Mobrey</strong> MSM400 is a microprocessor based electronic control unit. It operates with sensors mounted in a pipesection or suspended in a tank. The MSM400 monitors the suspended solids concentration in the liquid betweenthe two sensor faces. The normal application is to monitor this percentage, typically in the range 0.5% to 15%, toprovide signals for a plant control system to operate the slurry transport process. Typically this might be to desludge asewage settlement tank, or in mineral processing to maintain the percent solids of china clay, or similar, moving on tofurther refiners.The technique used to measure suspended solids is ultrasonic attenuation. As suspended solids pass between thegap in the sensor faces they scatter the ultrasound. The amount of signal that the sensor receives is inverslyproportional to the % of suspended solids.To allow accurate measurement over a wide range of % solids the attenuation is measured at 2 different frequencies.Control signals :The MSM400 has a 4-20mA, 2 relays and analogue output, typically 4-20mA, The MSM400 can control a desludgeoperation using a combination of measured % solids, external trigger and internal timers.The unit is also HART compatible, to feed in to digital control systems using HART protocol.A typical application would be with the sensors mounted in a discharge line from a refiner or settlement tank. Therelay in the MSM400 would be used to stop the de-sludge cycle when the liquor runs clear, switching at typicallyabout 4-5% suspended solids.The ultrasonic technique has an advantage over some techniques in that it is largelyunaffected by fouling of the sensor face.5IP258