DELIVERING THE CIRCULAR ECONOMY A TOOLKIT FOR POLICYMAKERS

20150924_Policymakers-Toolkit_Active-links

20150924_Policymakers-Toolkit_Active-links

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DELIVERING</strong> <strong>THE</strong> <strong>CIRCULAR</strong> <strong>ECONOMY</strong> – A <strong>TOOLKIT</strong> <strong>FOR</strong> <strong>POLICYMAKERS</strong> • 127<br />

facturing by definition restores a component to an ‘as new’ condition, it would<br />

be viable to use components again in new products, provided the dimensionality<br />

and design is consistent over product generations. This would save significant<br />

costs as both the raw material value and most value added from manufacturing<br />

the components are retained. This opportunity resembles Ricoh’s business model<br />

for office printers.<br />

By leveraging the circular economy building blocks and utilising both these<br />

opportunities, the Danish machinery sector could gradually adopt remanufacturing and<br />

refurbishment. A conservative estimate is that half of all product components could be<br />

addressed for remanufacturing. Until 2020, they would likely focus on sales to secondary<br />

markets, while by 2035, 15–50% of remanufactured components could be used in new<br />

products rather than sold to a secondary market. Figure 31 gives an overview of the<br />

estimated potential adoption rates and value creation estimated on a component level<br />

for two machinery products, wind turbines and pumps. Overall, this would contribute to<br />

net value creations of 1–3% as share of overall product costs by 2020, increasing to 4–9%<br />

by 2035. These findings give a directional view of the magnitude of this opportunity for<br />

Denmark. They rely by necessity on a number of assumptions, the most important of<br />

which are detailed in Appendix B. It should be emphasised that the estimates take into<br />

account the significant challenges of remanufacturing and refurbishment of long-lived<br />

equipment, such as liquid pumps and wind turbines.<br />

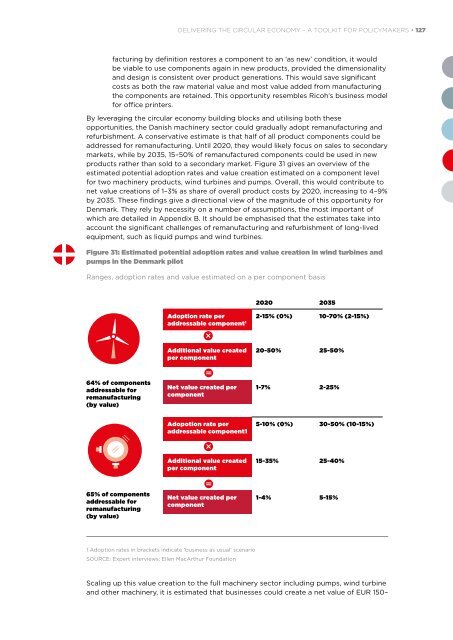

Figure 31: Estimated potential adoption rates and value creation in wind turbines and<br />

pumps in the Denmark pilot<br />

Ranges, adoption rates and value estimated on a per component basis<br />

2020 2035<br />

Adoption rate per<br />

2-15% (0%) 10-70% (2-15%)<br />

addressable component 1<br />

Additional value created<br />

per component<br />

20-50% 25-50%<br />

64% of components<br />

addressable for<br />

remanufacturing<br />

(by value)<br />

Net value created per<br />

component<br />

1-7% 2-25%<br />

Adopotion rate per<br />

addressable component1<br />

5-10% (0%) 30-50% (10-15%)<br />

Additional value created<br />

per component<br />

15-35% 25-40%<br />

65% of components<br />

addressable for<br />

remanufacturing<br />

(by value)<br />

Net value created per<br />

component<br />

1-4% 5-15%<br />

1 Adoption rates in brackets indicate ‘business as usual’ scenario<br />

SOURCE: Expert interviews; Ellen MacArthur Foundation<br />

Scaling up this value creation to the full machinery sector including pumps, wind turbine<br />

and other machinery, it is estimated that businesses could create a net value of EUR 150–