ANNUAL%20REPORT%202015%20eng

ANNUAL%20REPORT%202015%20eng

ANNUAL%20REPORT%202015%20eng

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

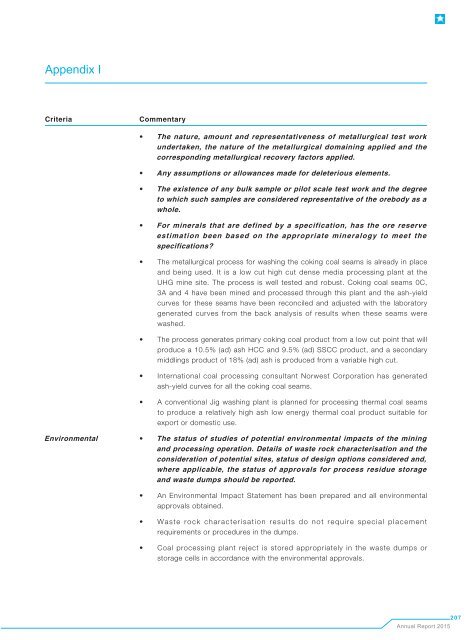

Appendix I<br />

Criteria<br />

Commentary<br />

• The nature, amount and representativeness of metallurgical test work<br />

undertaken, the nature of the metallurgical domaining applied and the<br />

corresponding metallurgical recovery factors applied.<br />

• Any assumptions or allowances made for deleterious elements.<br />

• The existence of any bulk sample or pilot scale test work and the degree<br />

to which such samples are considered representative of the orebody as a<br />

whole.<br />

• For minerals that are defined by a specification, has the ore reserve<br />

estimation been based on the appropriate mineralogy to meet the<br />

specifications?<br />

• The metallurgical process for washing the coking coal seams is already in place<br />

and being used. It is a low cut high cut dense media processing plant at the<br />

UHG mine site. The process is well tested and robust. Coking coal seams 0C,<br />

3A and 4 have been mined and processed through this plant and the ash-yield<br />

curves for these seams have been reconciled and adjusted with the laboratory<br />

generated curves from the back analysis of results when these seams were<br />

washed.<br />

• The process generates primary coking coal product from a low cut point that will<br />

produce a 10.5% (ad) ash HCC and 9.5% (ad) SSCC product, and a secondary<br />

middlings product of 18% (ad) ash is produced from a variable high cut.<br />

• International coal processing consultant Norwest Corporation has generated<br />

ash-yield curves for all the coking coal seams.<br />

• A conventional Jig washing plant is planned for processing thermal coal seams<br />

to produce a relatively high ash low energy thermal coal product suitable for<br />

export or domestic use.<br />

Environmental • The status of studies of potential environmental impacts of the mining<br />

and processing operation. Details of waste rock characterisation and the<br />

consideration of potential sites, status of design options considered and,<br />

where applicable, the status of approvals for process residue storage<br />

and waste dumps should be reported.<br />

• An Environmental Impact Statement has been prepared and all environmental<br />

approvals obtained.<br />

• Waste rock characterisation results do not require special placement<br />

requirements or procedures in the dumps.<br />

• Coal processing plant reject is stored appropriately in the waste dumps or<br />

storage cells in accordance with the environmental approvals.<br />

Annual Report 2015<br />

207