ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>HSD</strong><br />

9.6 EXTERNAL TOOL COOLING<br />

For the external tool cooling use water with the following specifications:<br />

� Index of aggressiveness (I.A) = 11-12<br />

� Electrical conductivity: not more than 600 microS/cm<br />

� Turbidity not above 20 mg/l<br />

� Chlorides not above 300 mg/l<br />

i<br />

Only an accurate analysis will tell if the water used for the machining process has the<br />

required physical characteristics.<br />

Do not use products containing sodium chloride (NaCl), which cause corrosion<br />

(rust).<br />

When using the <strong>HSD</strong> “Water flange” optional part, do not use de-scaling products<br />

in the external tool cooling circuit. De-scaling products will damage the watertightness<br />

of the “Water flange” unit.<br />

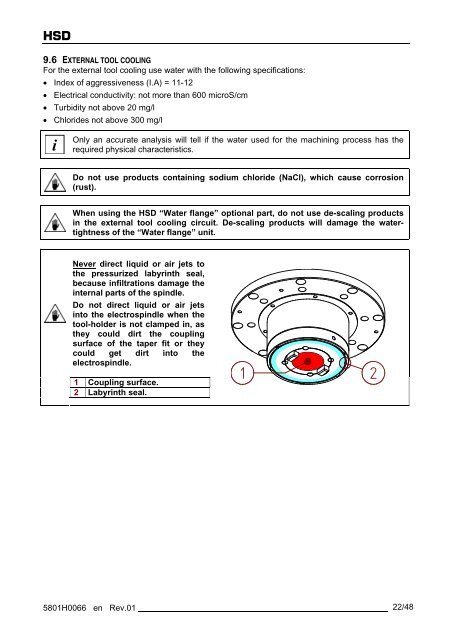

Never direct liquid or air jets to<br />

the pressurized labyrinth seal,<br />

because infiltrations damage the<br />

internal parts of the spindle.<br />

Do not direct liquid or air jets<br />

into the electrospindle when the<br />

tool-holder is not clamped in, as<br />

they could dirt the coupling<br />

surface of the taper fit or they<br />

could get dirt into the<br />

electrospindle.<br />

1 Coupling surface.<br />

2 Labyrinth seal.<br />

1 2<br />

5801H0066 en Rev.01 22/48