ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>HSD</strong><br />

9.8 PNEUMATIC CONNECTIONS<br />

i<br />

See the figures in paragraph 8.1 for the location and sizes of connections.<br />

See paragraph 7.1 for air consumptions.<br />

9.9 EXAMPLE OF COMPRESSED AIR CIRCUITS<br />

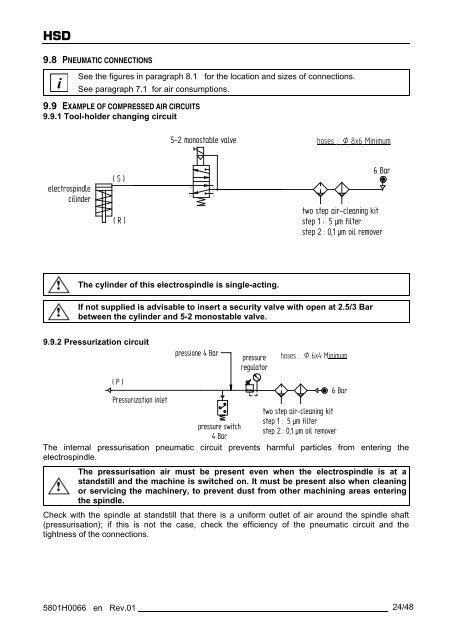

9.9.1 Tool-holder changing circuit<br />

electrospindle<br />

cilinder<br />

( S )<br />

( R )<br />

5-2 monostable valve<br />

The cylinder of this electrospindle is single-acting.<br />

4<br />

2<br />

1 5<br />

3<br />

hoses : Ø 8x6 Minimum<br />

two step air-cleaning kit<br />

step 1 : 5 μm filter<br />

step 2 : 0,1 μm oil remover<br />

If not supplied is advisable to insert a security valve with open at 2.5/3 Bar<br />

between the cylinder and 5-2 monostable valve.<br />

9.9.2 Pressurization circuit<br />

pressione 4 Bar<br />

pressure<br />

regulator<br />

hoses : Ø 6x4 Minimum<br />

( P )<br />

6 Bar<br />

Pressurization inlet<br />

pressure switch<br />

4 Bar<br />

two step air-cleaning kit<br />

step 1 : 5 μm filter<br />

step 2 : 0,1 μm oil remover<br />

The internal pressurisation pneumatic circuit prevents harmful particles from entering the<br />

electrospindle.<br />

5801H0066 en Rev.01 24/48<br />

6 Bar<br />

The pressurisation air must be present even when the electrospindle is at a<br />

standstill and the machine is switched on. It must be present also when cleaning<br />

or servicing the machinery, to prevent dust from other machining areas entering<br />

the spindle.<br />

Check with the spindle at standstill that there is a uniform outlet of air around the spindle shaft<br />

(pressurisation); if this is not the case, check the efficiency of the pneumatic circuit and the<br />

tightness of the connections.