ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>HSD</strong><br />

10.11 CHOICE OF TOOL<br />

The following requirements must be respected when choosing a tool:<br />

1. Only use perfectly sharp tools. Make sure that they are locked firmly in the toolholder.<br />

2. Never use bent, damaged, incomplete, or imperfectly balanced tools.<br />

3. Always make sure that the surfaces of the tool are clean and undamaged before fitting it in the<br />

collet.<br />

Never operate tools beyond the rated speed punched on them or that<br />

specified by the manufacturer.<br />

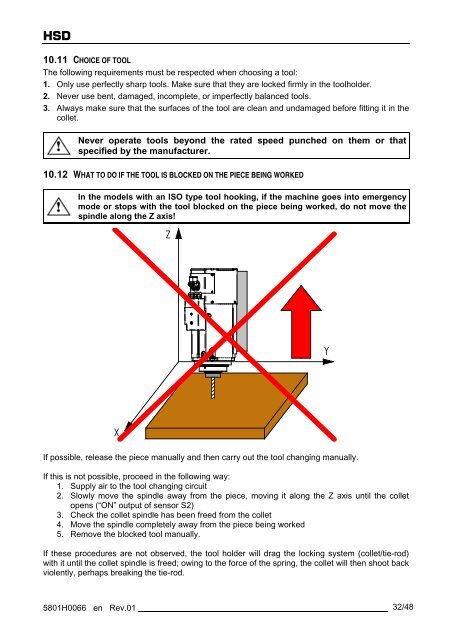

10.12 WHAT TO DO IF THE TOOL IS BLOCKED ON THE PIECE BEING WORKED<br />

In the models with an ISO type tool hooking, if the machine goes into emergency<br />

mode or stops with the tool blocked on the piece being worked, do not move the<br />

spindle along the Z axis!<br />

X<br />

Z<br />

If possible, release the piece manually and then carry out the tool changing manually.<br />

If this is not possible, proceed in the following way:<br />

1. Supply air to the tool changing circuit<br />

2. Slowly move the spindle away from the piece, moving it along the Z axis until the collet<br />

opens (“ON” output of sensor S2)<br />

3. Check the collet spindle has been freed from the collet<br />

4. Move the spindle completely away from the piece being worked<br />

5. Remove the blocked tool manually.<br />

If these procedures are not observed, the tool holder will drag the locking system (collet/tie-rod)<br />

with it until the collet spindle is freed; owing to the force of the spring, the collet will then shoot back<br />

violently, perhaps breaking the tie-rod.<br />

5801H0066 en Rev.01 32/48<br />

Y