ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

ES721 ISO40 7 kW NL - HSD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>HSD</strong><br />

11.1 DAILY MAINTENANCE<br />

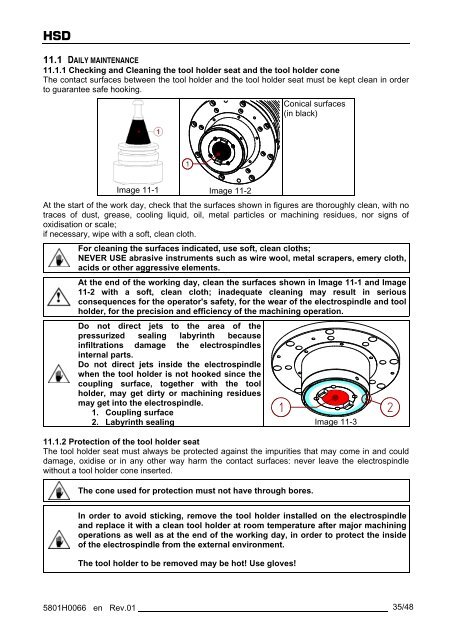

11.1.1 Checking and Cleaning the tool holder seat and the tool holder cone<br />

The contact surfaces between the tool holder and the tool holder seat must be kept clean in order<br />

to guarantee safe hooking.<br />

Image 11-1<br />

1<br />

Image 11-2<br />

Conical surfaces<br />

(in black)<br />

At the start of the work day, check that the surfaces shown in figures are thoroughly clean, with no<br />

traces of dust, grease, cooling liquid, oil, metal particles or machining residues, nor signs of<br />

oxidisation or scale;<br />

if necessary, wipe with a soft, clean cloth.<br />

For cleaning the surfaces indicated, use soft, clean cloths;<br />

NEVER USE abrasive instruments such as wire wool, metal scrapers, emery cloth,<br />

acids or other aggressive elements.<br />

At the end of the working day, clean the surfaces shown in Image 11-1 and Image<br />

11-2 with a soft, clean cloth; inadequate cleaning may result in serious<br />

consequences for the operator's safety, for the wear of the electrospindle and tool<br />

holder, for the precision and efficiency of the machining operation.<br />

Do not direct jets to the area of the<br />

pressurized sealing labyrinth because<br />

infiltrations damage the electrospindles<br />

internal parts.<br />

Do not direct jets inside the electrospindle<br />

when the tool holder is not hooked since the<br />

coupling surface, together with the tool<br />

holder, may get dirty or machining residues<br />

may get into the electrospindle.<br />

1. Coupling surface<br />

2. Labyrinth sealing<br />

1 2<br />

Image 11-3<br />

11.1.2 Protection of the tool holder seat<br />

The tool holder seat must always be protected against the impurities that may come in and could<br />

damage, oxidise or in any other way harm the contact surfaces: never leave the electrospindle<br />

without a tool holder cone inserted.<br />

The cone used for protection must not have through bores.<br />

In order to avoid sticking, remove the tool holder installed on the electrospindle<br />

and replace it with a clean tool holder at room temperature after major machining<br />

operations as well as at the end of the working day, in order to protect the inside<br />

of the electrospindle from the external environment.<br />

The tool holder to be removed may be hot! Use gloves!<br />

5801H0066 en Rev.01 35/48