At the Cutting Edge of Beverage Filling - Verpackungs-Rundschau

At the Cutting Edge of Beverage Filling - Verpackungs-Rundschau

At the Cutting Edge of Beverage Filling - Verpackungs-Rundschau

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

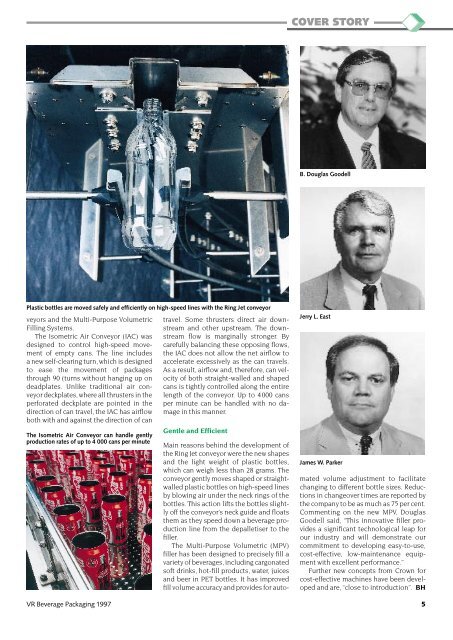

Plastic bottles are moved safely and efficiently on high-speed lines with <strong>the</strong> Ring Jet conveyor<br />

veyors and <strong>the</strong> Multi-Purpose Volumetric<br />

<strong>Filling</strong> Systems.<br />

The Isometric Air Conveyor (IAC) was<br />

designed to control high-speed movement<br />

<strong>of</strong> empty cans. The line includes<br />

a new self-clearing turn,which is designed<br />

to ease <strong>the</strong> movement <strong>of</strong> packages<br />

through 90 (turns without hanging up on<br />

deadplates. Unlike traditional air conveyor<br />

deckplates,where all thrusters in <strong>the</strong><br />

perforated deckplate are pointed in <strong>the</strong><br />

direction <strong>of</strong> can travel, <strong>the</strong> IAC has airflow<br />

both with and against <strong>the</strong> direction <strong>of</strong> can<br />

The Isometric Air Conveyor can handle gently<br />

production rates <strong>of</strong> up to 4 000 cans per minute<br />

travel. Some thrusters direct air downstream<br />

and o<strong>the</strong>r upstream. The downstream<br />

flow is marginally stronger. By<br />

carefully balancing <strong>the</strong>se opposing flows,<br />

<strong>the</strong> IAC does not allow <strong>the</strong> net airflow to<br />

accelerate excessively as <strong>the</strong> can travels.<br />

As a result, airflow and, <strong>the</strong>refore, can velocity<br />

<strong>of</strong> both straight-walled and shaped<br />

cans is tightly controlled along <strong>the</strong> entire<br />

length <strong>of</strong> <strong>the</strong> conveyor. Up to 4000 cans<br />

per minute can be handled with no damage<br />

in this manner.<br />

Gentle and Efficient<br />

Main reasons behind <strong>the</strong> development <strong>of</strong><br />

<strong>the</strong> Ring Jet conveyor were <strong>the</strong> new shapes<br />

and <strong>the</strong> light weight <strong>of</strong> plastic bottles,<br />

which can weigh less than 28 grams. The<br />

conveyor gently moves shaped or straightwalled<br />

plastic bottles on high-speed lines<br />

by blowing air under <strong>the</strong> neck rings <strong>of</strong> <strong>the</strong><br />

bottles. This action lifts <strong>the</strong> bottles slightly<br />

<strong>of</strong>f <strong>the</strong> conveyor’s neck guide and floats<br />

<strong>the</strong>m as <strong>the</strong>y speed down a beverage production<br />

line from <strong>the</strong> depalletiser to <strong>the</strong><br />

filler.<br />

The Multi-Purpose Volumetric (MPV)<br />

filler has been designed to precisely fill a<br />

variety <strong>of</strong> beverages, including cargonated<br />

s<strong>of</strong>t drinks, hot-fill products, water, juices<br />

and beer in PET bottles. It has improved<br />

fill volume accuracy and provides for auto-<br />

COVER STORY<br />

B. Douglas Goodell<br />

Jerry L. East<br />

James W. Parker<br />

mated volume adjustment to facilitate<br />

changing to different bottle sizes. Reductions<br />

in changeover times are reported by<br />

<strong>the</strong> company to be as much as 75 per cent.<br />

Commenting on <strong>the</strong> new MPV, Douglas<br />

Goodell said, “This innovative filler provides<br />

a significant technological leap for<br />

our industry and will demonstrate our<br />

commitment to developing easy-to-use,<br />

cost-effective, low-maintenance equipment<br />

with excellent performance.”<br />

Fur<strong>the</strong>r new concepts from Crown for<br />

cost-effective machines have been developed<br />

and are, “close to introduction”. BH<br />

VR <strong>Beverage</strong> Packaging 1997 5