Reviewer Comments - EERE

Reviewer Comments - EERE

Reviewer Comments - EERE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2011 Algae Platform Review – <strong>Reviewer</strong> <strong>Comments</strong><br />

<strong>Reviewer</strong> <strong>Comments</strong> are direct transcripts of commentary and material provided by the Platform’s<br />

Review Panel. They have not been edited or altered by the Biomass Program.<br />

conditions that prevent membrane fouling, the cost changes to $2.03 x 10E-5 per gallon for the filtration<br />

process or $243.80. No CapX were included in any of these estimates. We recognize that these<br />

preliminary calculations need significant refinement, but they provide an initial basis to warrant further<br />

investigation both from cost and experimental perspectives. Due to the combined complexity of the<br />

estimation and space limitations, we are open to discuss this further with reviewer. We do not fully agree<br />

with this comment that the presenter had a technology that “he can make work” for this particular<br />

application. Once again we apologize for any misperception that this is a technology in search of an<br />

application. We carefully evaluated costs for different filtration methods and came down with the two<br />

scenarios and further we provide the costs per gallon in the above examples which are surprisingly<br />

insensitive to method, but the level of solids (%solids) varies vastly ( Scenario 1 = 50 – 60%, Scenario 2<br />

= 15 – 20%) . We hope to consume much less than 15% of total energy, but need to optimize the<br />

debottlenecking separation of water and algae, thus the focused effort. Basically, it is not economic to<br />

filter all of the water in the raceway so a pre-concentration must be performed. There are three main<br />

approaches to pre-concentration: 1) full volume evaporation (used as a pre-concentration step much as<br />

does the salt industry, but the algae will probably eat up their stored oils to survive these types of<br />

scenarios thus rendering them nearly useless to us for oil production), 2) gravity assisted<br />

flocculation/settling, and 3) air (or other gas) assisted floatation. All of these methods are commonly<br />

utilized in industry (food processing, mining, etc.). We have selected gas assisted flotation due to its<br />

consistent results, speed, high concentration ratios, and energy efficiency. We are pursuing very smallscale<br />

studies with several varieties of algae to understand how the systems will perform before going to<br />

the expense of purchasing a full scale rotary membrane unit. We have read a number or TEA articles and<br />

will continue to consider the techno-economic feasibility of the cross-flow membrane technology.<br />

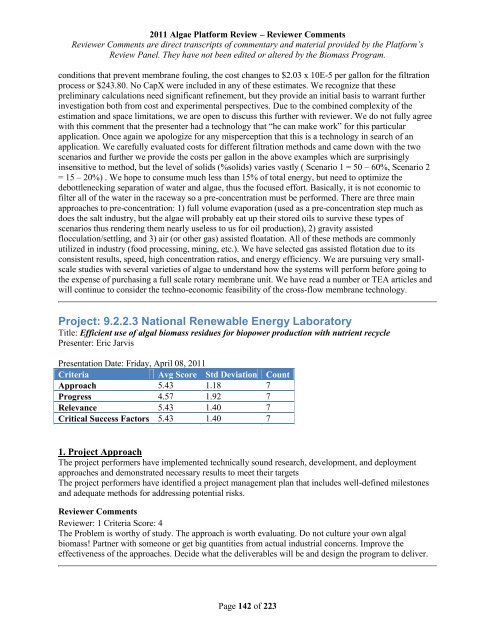

Project: 9.2.2.3 National Renewable Energy Laboratory<br />

Title: Efficient use of algal biomass residues for biopower production with nutrient recycle<br />

Presenter: Eric Jarvis<br />

Presentation Date: Friday, April 08, 2011<br />

Criteria Avg Score Std Deviation Count<br />

Approach 5.43 1.18 7<br />

Progress 4.57 1.92 7<br />

Relevance 5.43 1.40 7<br />

Critical Success Factors 5.43 1.40 7<br />

1. Project Approach<br />

The project performers have implemented technically sound research, development, and deployment<br />

approaches and demonstrated necessary results to meet their targets<br />

The project performers have identified a project management plan that includes well-defined milestones<br />

and adequate methods for addressing potential risks.<br />

<strong>Reviewer</strong> <strong>Comments</strong><br />

<strong>Reviewer</strong>: 1 Criteria Score: 4<br />

The Problem is worthy of study. The approach is worth evaluating. Do not culture your own algal<br />

biomass! Partner with someone or get big quantities from actual industrial concerns. Improve the<br />

effectiveness of the approaches. Decide what the deliverables will be and design the program to deliver.<br />

Page 142 of 223