Fuxx Control - ARS 2320 / ARS 2340 Instruction Manual - Kuhnke

Fuxx Control - ARS 2320 / ARS 2340 Instruction Manual - Kuhnke

Fuxx Control - ARS 2320 / ARS 2340 Instruction Manual - Kuhnke

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

KUHNKE Automation <strong>Fuxx</strong> <strong>Control</strong> <strong>ARS</strong> <strong>2320</strong> / <strong>ARS</strong> <strong>2340</strong><br />

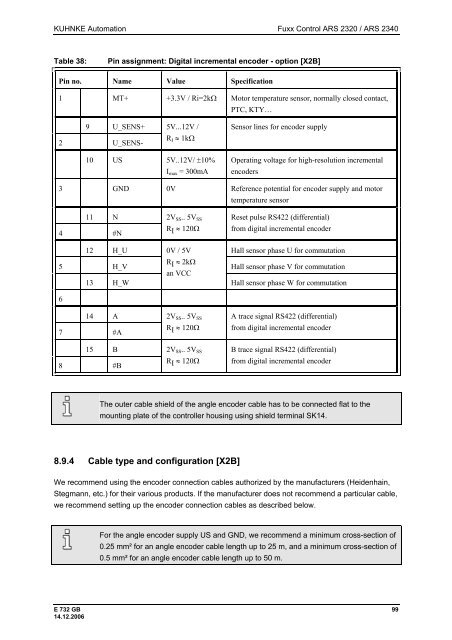

Table 38: Pin assignment: Digital incremental encoder - option [X2B]<br />

Pin no. Name Value Specification<br />

1 MT+ +3.3V / Ri=2kΩ Motor temperature sensor, normally closed contact,<br />

PTC, KTY…<br />

9 U_SENS+<br />

2 U_SENS-<br />

5V...12V /<br />

RI ≈ 1kΩ<br />

10 US 5V..12V/ ±10%<br />

Imax = 300mA<br />

Sensor lines for encoder supply<br />

Operating voltage for high-resolution incremental<br />

encoders<br />

3 GND 0V Reference potential for encoder supply and motor<br />

temperature sensor<br />

11 N<br />

4 #N<br />

2VSS.. 5VSS<br />

R I ≈ 120Ω<br />

Reset pulse RS422 (differential)<br />

from digital incremental encoder<br />

12 H_U 0V / 5V<br />

Hall sensor phase U for commutation<br />

5 H_V<br />

RI ≈ 2kΩ<br />

an VCC<br />

Hall sensor phase V for commutation<br />

13 H_W<br />

Hall sensor phase W for commutation<br />

6<br />

14 A<br />

7 #A<br />

15 B<br />

8 #B<br />

2VSS.. 5VSS<br />

R I ≈ 120Ω<br />

2VSS.. 5VSS<br />

R I ≈ 120Ω<br />

A trace signal RS422 (differential)<br />

from digital incremental encoder<br />

B trace signal RS422 (differential)<br />

from digital incremental encoder<br />

The outer cable shield of the angle encoder cable has to be connected flat to the<br />

mounting plate of the controller housing using shield terminal SK14.<br />

8.9.4 Cable type and configuration [X2B]<br />

We recommend using the encoder connection cables authorized by the manufacturers (Heidenhain,<br />

Stegmann, etc.) for their various products. If the manufacturer does not recommend a particular cable,<br />

we recommend setting up the encoder connection cables as described below.<br />

For the angle encoder supply US and GND, we recommend a minimum cross-section of<br />

0.25 mm² for an angle encoder cable length up to 25 m, and a minimum cross-section of<br />

0.5 mm² for an angle encoder cable length up to 50 m.<br />

E 732 GB 99<br />

14.12.2006