The Turbo Air® 3000 Centrifugal Compressor Compressor Handbook

The Turbo Air® 3000 Centrifugal Compressor Compressor Handbook

The Turbo Air® 3000 Centrifugal Compressor Compressor Handbook

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

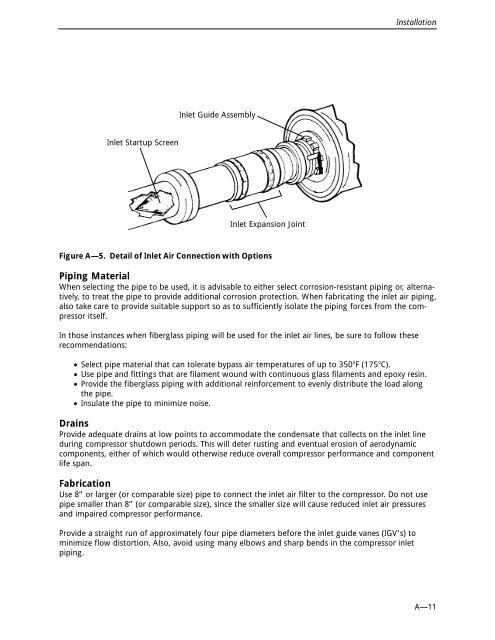

Inlet Startup Screen<br />

Inlet Guide Assembly<br />

Inlet Expansion Joint<br />

Figure A—5. Detail of Inlet Air Connection with Options<br />

Installation<br />

Piping Material<br />

When selecting the pipe to be used, it is advisable to either select corrosion-resistant piping or, alternatively,<br />

to treat the pipe to provide additional corrosion protection. When fabricating the inlet air piping,<br />

also take care to provide suitable support so as to sufficiently isolate the piping forces from the compressor<br />

itself.<br />

In those instances when fiberglass piping will be used for the inlet air lines, be sure to follow these<br />

recommendations:<br />

· Select pipe material that can tolerate bypass air temperatures of up to 350°F (175°C).<br />

· Use pipe and fittings that are filament wound with continuous glass filaments and epoxy resin.<br />

· Provide the fiberglass piping with additional reinforcement to evenly distribute the load along<br />

the pipe.<br />

· Insulate the pipe to minimize noise.<br />

Drains<br />

Provide adequate drains at low points to accommodate the condensate that collects on the inlet line<br />

during compressor shutdown periods. This will deter rusting and eventual erosion of aerodynamic<br />

components, either of which would otherwise reduce overall compressor performance and component<br />

life span.<br />

Fabrication<br />

Use 8” or larger (or comparable size) pipe to connect the inlet air filter to the compressor. Do not use<br />

pipe smaller than 8” (or comparable size), since the smaller size will cause reduced inlet air pressures<br />

and impaired compressor performance.<br />

Provide a straight run of approximately four pipe diameters before the inlet guide vanes (IGV’s) to<br />

minimize flow distortion. Also, avoid using many elbows and sharp bends in the compressor inlet<br />

piping.<br />

A—11