You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Evaluation of a universal transitional resistance diagram for pipes<br />

with honed surfaces<br />

J.J. Allen a, M.A. Shockling b and A.J. Smits b<br />

A method for evaluating a universal transitional resistance diagram for pipes that<br />

relates the pressure drop in the pipe to Reynolds number, as a function of relative<br />

surface roughness, is presented. The method assumes a universal wake function<br />

coupled with a logarithmic overlap region and a power fit in the viscous and buffer<br />

layer. Estimates can be made of the friction factor-Reynolds number relationship for<br />

arbitrary relative roughness. The method is illustrated for a pipe with a honed surface<br />

finish. The size of the non-dimensional velocity shift as a function of roughness<br />

Reynolds number comes from the honed pipe data of Shockling 1 which had a ratio of<br />

pipe diameter to roughness height of 40x10 3. Honed roughness demonstrates an<br />

inflectional behavior in the transitionally rough regime, much like sandgrain<br />

roughness 2, but the method proposed here applies to any given roughness behavior.<br />

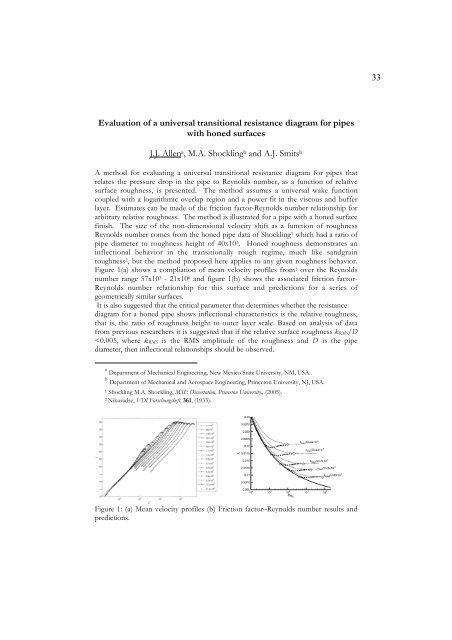

Figure 1(a) shows a compliation of mean velocity profiles from 1 over the Reynolds<br />

number range 57x10 3 - 21x10 6 and figure 1(b) shows the associated friction factor-<br />

Reynolds number relationship for this surface and predictions for a series of<br />

geometrically similar surfaces.<br />

It is also suggested that the critical parameter that determines whether the resistance<br />

diagram for a honed pipe shows inflectional characteristics is the relative roughness,<br />

that is, the ratio of roughness height to outer layer scale. Based on analysis of data<br />

from previous researchers it is suggested that if the relative surface roughness kRMS/D<br />