View - DSpace UniPR

View - DSpace UniPR

View - DSpace UniPR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PNA Microcontact Printing<br />

case the signals are weaker, and this may be due to the steric hindrance of the surface, which<br />

might be an important factor for long DNA sequences and could be more relevant if even<br />

longer sequences are used.<br />

5.2.4 PNA Microarrays fabrication by microcontact printing<br />

The good results obtained by derivatizing surfaces using this technique, the short time<br />

necessary to fabricate the devices, and the quality of the recognition process when PNAs were<br />

linked to surface, led us to explore the possibility to couple µCP with an existing technology<br />

in order to fabricate microarrays.<br />

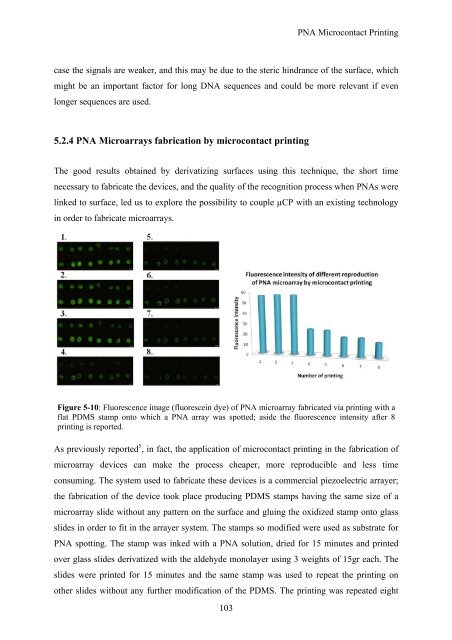

Figure 5-10: Fluorescence image (fluorescein dye) of PNA microarray fabricated via printing with a<br />

flat PDMS stamp onto which a PNA array was spotted; aside the fluorescence intensity after 8<br />

printing is reported.<br />

As previously reported 5 , in fact, the application of microcontact printing in the fabrication of<br />

microarray devices can make the process cheaper, more reproducible and less time<br />

consuming. The system used to fabricate these devices is a commercial piezoelectric arrayer;<br />

the fabrication of the device took place producing PDMS stamps having the same size of a<br />

microarray slide without any pattern on the surface and gluing the oxidized stamp onto glass<br />

slides in order to fit in the arrayer system. The stamps so modified were used as substrate for<br />

PNA spotting. The stamp was inked with a PNA solution, dried for 15 minutes and printed<br />

over glass slides derivatized with the aldehyde monolayer using 3 weights of 15gr each. The<br />

slides were printed for 15 minutes and the same stamp was used to repeat the printing on<br />

other slides without any further modification of the PDMS. The printing was repeated eight<br />

103