View - DSpace UniPR

View - DSpace UniPR

View - DSpace UniPR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PNA Microcontact Printing<br />

surface 19 . The immobilization on glass or silicon can be done by activating the surface<br />

through reactive monolayers such as isothiocyanate 20 , N-hydroxysuccinimidyl 21,22 or<br />

aldehydic 23 groups used to link the amino-end; click chemistry has been exploited, as well, in<br />

a reaction between an acetylene-modified surface and an azido-coumarin modified-PNA 24 .<br />

Moreover coupling of PNAs to nanoparticles has been studied as well; these systems have<br />

been developed by coupling the PNA directly through its amino group to the nanoparticle by<br />

EDC mediated coupling 25 , or by click chemistry 26 and their aggregation has been studied with<br />

complementary DNA sequences.<br />

Although the combination of PNA probes with the microarray technology can show good<br />

performances, the fabrication methods are still time consuming and good performances can<br />

usually be achieved only under strictly controlled moisture and temperature conditions which<br />

are not always reproducible 24 . One way to improve the fabrication of these devices on surface,<br />

is to derivatize the surface by microcontact printing (µCP).<br />

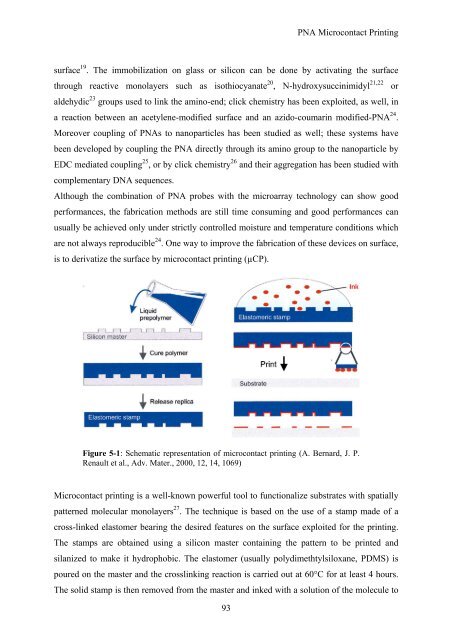

Figure 5-1: Schematic representation of microcontact printing (A. Bernard, J. P.<br />

Renault et al., Adv. Mater., 2000, 12, 14, 1069)<br />

Microcontact printing is a well-known powerful tool to functionalize substrates with spatially<br />

patterned molecular monolayers 27 . The technique is based on the use of a stamp made of a<br />

cross-linked elastomer bearing the desired features on the surface exploited for the printing.<br />

The stamps are obtained using a silicon master containing the pattern to be printed and<br />

silanized to make it hydrophobic. The elastomer (usually polydimethtylsiloxane, PDMS) is<br />

poured on the master and the crosslinking reaction is carried out at 60°C for at least 4 hours.<br />

The solid stamp is then removed from the master and inked with a solution of the molecule to<br />

93