Annual Report 2010 - Outokumpu

Annual Report 2010 - Outokumpu

Annual Report 2010 - Outokumpu

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

46<br />

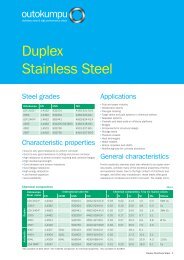

Duplex grades<br />

Demand for ferritic-austenitic duplex grades is growing significantly faster than demand for standard stainless grades. In<br />

addition to its low nickel content, duplex stainless steel is characterised by good corrosion resistance and high strength,<br />

allowing thinner gauges to be used in a variety of applications such as tanks, pressure vessels, piping, transportation,<br />

building and construction, and desalination plants. Considerable reductions in material costs can be achieved.<br />

<strong>Outokumpu</strong> is the clear market leader in duplex grade stainless steel with a global market share of some 50%. The<br />

Group's Avesta Works has a long and successful track record in the very demanding process of duplex production.<br />

<strong>Outokumpu</strong> LDX 2101 ® , a lean duplex grade developed and patented by <strong>Outokumpu</strong>, has a nickel content of only 1.5%,<br />

making its price less dependent on the volatile price of nickel. In terms of corrosion resistance, LDX performance is<br />

similar to that of standard austenitic 304 grade (8% nickel), but <strong>Outokumpu</strong>'s lean duplex stainless steel is twice as<br />

strong as the standard grade and has met with great success in demanding applications. To facilitate market penetration,<br />

<strong>Outokumpu</strong> has granted LDX 2101 ® manufacturing licences to a number of stainless steel producers in Europe and Asia.<br />

A new member of the <strong>Outokumpu</strong> lean duplex family was launched in <strong>2010</strong>. <strong>Outokumpu</strong> LDX 2404 ® has a 3.6% nickel<br />

content and is well positioned in relation to 316L, the acid-resistant standard austenitic grade (10% nickel). As LDX<br />

2404 ® has a higher chrome and nitrogen content than 316, it offers higher levels of corrosion resistance, making it an<br />

excellent choice for the salty atmospheric conditions which prevail in buildings located near the sea. The higher<br />

mechanical strength of LDX 2404 ® also allows the use of thinner gauges, offering additional benefits in bulk liquid<br />

storage tanks, road and rail tankers, pulp and paper machinery and water-treatment facilities. The combination of<br />

improved corrosion resistance and higher strength makes LDX 2404 ® a very cost-effective solution in such applications.<br />

<strong>Outokumpu</strong> <strong>Annual</strong> <strong>Report</strong> <strong>2010</strong> – Business – Duplex grades