Central Rice Research Institute Annual report...2011-12

Central Rice Research Institute Annual report...2011-12

Central Rice Research Institute Annual report...2011-12

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mechanization for <strong>Rice</strong> Production and Post-harvest Systems<br />

Mechanization for <strong>Rice</strong><br />

Production and Post-harvest<br />

Systems<br />

Development of Cost Effective Machines<br />

Design, fabrication and testing of self<br />

propelled paddy hill seeder, power tiller<br />

operated multi-crop seed drill<br />

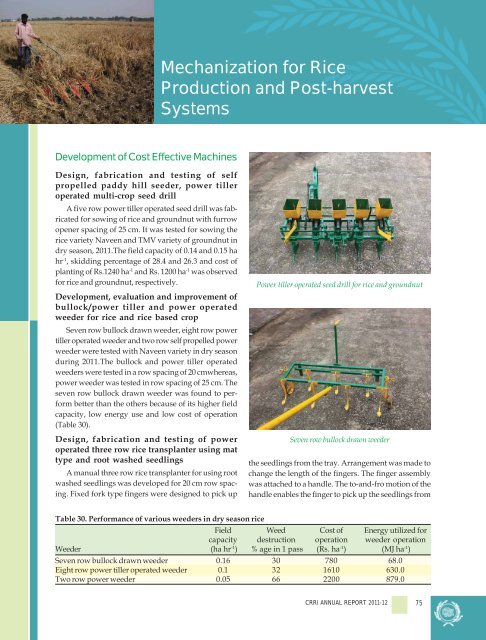

A five row power tiller operated seed drill was fabricated<br />

for sowing of rice and groundnut with furrow<br />

opener spacing of 25 cm. It was tested for sowing the<br />

rice variety Naveen and TMV variety of groundnut in<br />

dry season, 2011.The field capacity of 0.14 and 0.15 ha<br />

hr -1 , skidding percentage of 28.4 and 26.3 and cost of<br />

planting of Rs.<strong>12</strong>40 ha -1 and Rs. <strong>12</strong>00 ha -1 was observed<br />

for rice and groundnut, respectively.<br />

Development, evaluation and improvement of<br />

bullock/power tiller and power operated<br />

weeder for rice and rice based crop<br />

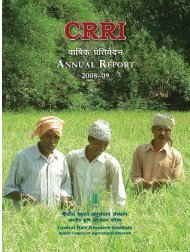

Seven row bullock drawn weeder, eight row power<br />

tiller operated weeder and two row self propelled power<br />

weeder were tested with Naveen variety in dry season<br />

during 2011.The bullock and power tiller operated<br />

weeders were tested in a row spacing of 20 cmwhereas,<br />

power weeder was tested in row spacing of 25 cm. The<br />

seven row bullock drawn weeder was found to perform<br />

better than the others because of its higher field<br />

capacity, low energy use and low cost of operation<br />

(Table 30).<br />

Design, fabrication and testing of power<br />

operated three row rice transplanter using mat<br />

type and root washed seedlings<br />

A manual three row rice transplanter for using root<br />

washed seedlings was developed for 20 cm row spacing.<br />

Fixed fork type fingers were designed to pick up<br />

Power tiller operated seed drill for rice and groundnut<br />

Seven row bullock drawn weeder<br />

the seedlings from the tray. Arrangement was made to<br />

change the length of the fingers. The finger assembly<br />

was attached to a handle. The to-and-fro motion of the<br />

handle enables the finger to pick up the seedlings from<br />

Table 30. Performance of various weeders in dry season rice<br />

Field Weed Cost of Energy utilized for<br />

capacity destruction operation weeder operation<br />

Weeder (ha hr -1 ) % age in 1 pass (Rs. ha -1 ) (MJ ha -1 )<br />

Seven row bullock drawn weeder 0.16 30 780 68.0<br />

Eight row power tiller operated weeder 0.1 32 1610 630.0<br />

Two row power weeder 0.05 66 2200 879.0<br />

CRRI ANNUAL REPORT 2011-<strong>12</strong><br />

75