Central Rice Research Institute Annual report...2011-12

Central Rice Research Institute Annual report...2011-12

Central Rice Research Institute Annual report...2011-12

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the tray and plant them in the field. A mechanism was<br />

designed for the reciprocating motion of the seedling<br />

tray. The tray moves a little after each picking of the<br />

seedlings and moves in the reverse direction when the<br />

tray compartment reaches to a side. There is a mechanism<br />

to feed the seedlings in the tray to the fingers.<br />

Plant to plant distance is adjustable as per requirement<br />

of hill spacing. Field testing results revealed that the<br />

transplanter had field capacity of 0.011 ha hr -1 with<br />

missing hills ranging from 18-20%. This would be suitable<br />

for small size field.<br />

Development and evaluation of power<br />

operated pre-germinated paddy seeder<br />

An eight row, engine operated, pre-germinated<br />

paddy seeder having hyperboloid shape was designed<br />

with an aim to reduce the human drudgery in transplanting<br />

of paddy and reduce cost of cultivation. The<br />

machine comprised of a 2.94 kW light weight diesel<br />

engine, power transmission system, seed drum, main<br />

frame, float, ground wheel and tail wheel. This was<br />

field tested in wet season during 2011 and its performance<br />

was compared with the engine operated (8 rows)<br />

seeder having cylindrical shape, manual drum seeder<br />

having hyperboloid shape (8 rows), self propelled 8<br />

rows transplanter and manual transplanting (Control).<br />

The field capacity of the developed seeder was 0.235 ha<br />

hr -1 which was more than other tested seeders and rice<br />

transplanters(Table 31).<br />

Enhancing productivity, water use efficiency<br />

and profitability of rice cultivation system by<br />

use of CRRI planters and weeders<br />

The field performance of CRRI planters were evaluated<br />

during wet season with rice variety Gayatri. The<br />

study showed that sprouted drum seeder is the best<br />

technique to reduce the cost of wet land rice-planting<br />

where standing water condition allows its use (within<br />

2-5 mm). In case of higher water depth, mat type transplanters<br />

could be used with productivity advantage of<br />

3.3%). Maximum net returns (Rs. 21, 410 ha -1 , Table 32)<br />

from rice cultivation was obtained by use of the self<br />

propelled transplanter.<br />

The CRRI weeders were evaluated during dry season<br />

with rice variety Naveen. Among all the weeders,<br />

weed destruction was highest in case of cono weeder,<br />

followed by finger weeder and manual weeding. Average<br />

grain yield (3.85 t ha -1 ) and WUE (0.57 kg m -3 ) in<br />

mechanically weeded plots were twice the un-weeded<br />

plots. Highest net returns were obtained by using starconoweeder<br />

followed by power weeder.<br />

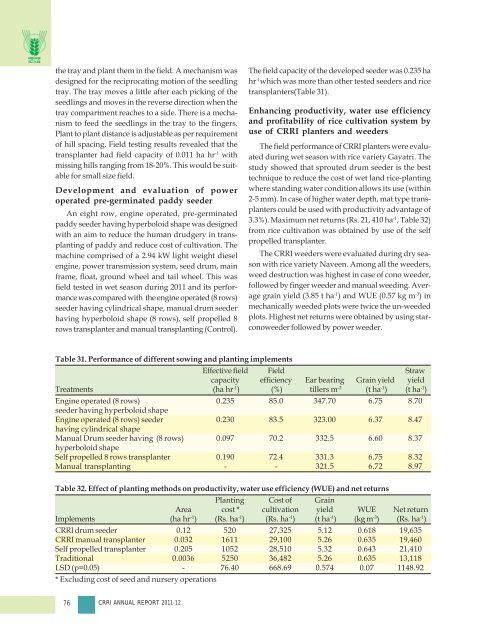

Table 31. Performance of different sowing and planting implements<br />

Effective field Field Straw<br />

capacity efficiency Ear bearing Grain yield yield<br />

Treatments (ha hr -1 ) (%) tillers m -2 (t ha -1 ) (t ha -1 )<br />

Engine operated (8 rows) 0.235 85.0 347.70 6.75 8.70<br />

seeder having hyperboloid shape<br />

Engine operated (8 rows) seeder 0.230 83.5 323.00 6.37 8.47<br />

having cylindrical shape<br />

Manual Drum seeder having (8 rows) 0.097 70.2 332.5 6.60 8.37<br />

hyperboloid shape<br />

Self propelled 8 rows transplanter 0.190 72.4 331.3 6.75 8.32<br />

Manual transplanting - - 321.5 6.72 8.97<br />

Table 32. Effect of planting methods on productivity, water use efficiency (WUE) and net returns<br />

Planting Cost of Grain<br />

Area cost * cultivation yield WUE Net return<br />

Implements (ha hr -1 ) (Rs. ha -1 ) (Rs. ha -1 ) (t ha -1 ) (kg m -3 ) (Rs. ha -1 )<br />

CRRI drum seeder 0.<strong>12</strong> 520 27,325 5.<strong>12</strong> 0.618 19,635<br />

CRRI manual transplanter 0.032 1611 29,100 5.26 0.635 19,460<br />

Self propelled transplanter 0.205 1052 28,510 5.32 0.643 21,410<br />

Traditional 0.0036 5250 36,482 5.26 0.635 13,118<br />

LSD (p=0.05) - 76.40 668.69 0.574 0.07 1148.92<br />

* Excluding cost of seed and nursery operations<br />

76 CRRI ANNUAL REPORT 2011-<strong>12</strong>