- Page 4:

Our philosophy is basedon a very si

- Page 7 and 8:

Perfect results through clean cuts!

- Page 9:

SawsYOU CAN TRUST ON ITtooth checki

- Page 13 and 14:

SawsKataba SawsBecause of their thi

- Page 16 and 17:

SawsJapanese SawsaSatisfactionGuara

- Page 18 and 19:

SawsSheet Japanese Saws with interc

- Page 20:

Sawsdeluxe-SawsHand-made - for the

- Page 24:

Sawsaa ORIKOMI FOLDING SAW 250,COAR

- Page 27 and 28:

SawsaBa LIE-NIELSEN ® CROSSCUT SAW

- Page 29 and 30:

Sawsfreeway ®• Robust steel fram

- Page 31 and 32:

SawsBaa SaW gUide SetPrecision saw

- Page 33 and 34: For perfect joints!Western Type | 3

- Page 35 and 36: ChiselsSatisfactionchiselsDICK chis

- Page 37: ChiselsJapanese TypeWherever absolu

- Page 41: Chiselsaa HATTORI ® CARPENTER‘SC

- Page 44 and 45: ChiselsTool Rolls and AccessoriesFo

- Page 46 and 47: Sculpting ToolsSculpting Toolseurop

- Page 48 and 49: Sculpting Toolspfeil carving toolsT

- Page 50 and 51: Sculpting ToolsWOrKShOpCARVED BOxaa

- Page 52 and 53: Sculpting Toolsaa PFEIL ALLONGEE GO

- Page 54 and 55: Sculpting Toolspfeil compact carvin

- Page 58 and 59: Sculpting Toolsnative americancarvi

- Page 60 and 61: Sculpting Toolsa ARBORTECH TURBOPLA

- Page 62 and 63: Sculpting Toolsa 152634Ba PFEIL WOO

- Page 64 and 65: Sculpting Toolspfeil-Woodcutting to

- Page 66 and 67: Sculpting ToolsSwedish typefrost ®

- Page 68 and 69: SatisfactionSculpting ToolsSculptor

- Page 70 and 71: Sculpting Toolsa B cdictUM satisfac

- Page 72 and 73: Hatchets and Axesgränsfors Bruks

- Page 74 and 75: Hatchets and Axesaxes and hatchetsw

- Page 76 and 77: Hatchets and Axesaa WETTERLINGS ®S

- Page 78 and 79: Hatchets and AxesJapanese axesWith

- Page 80: Hatchets and Axesaxes»A blacksmith

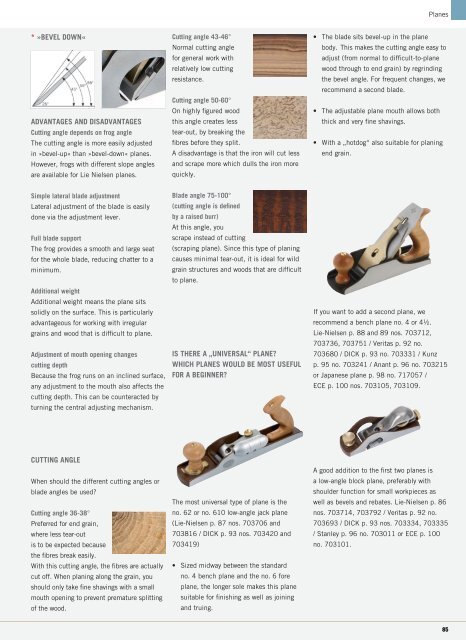

- Page 83: Lie-Nielsen ® Planes | 86Veritas

- Page 87 and 88: Planesa LIE-NIELSEN ®SHOULDER PLAN

- Page 89 and 90: Planesaa LIE-NIELSEN ®SMOOTHING PL

- Page 91 and 92: PlanesScraping planes• Scrape sur

- Page 93 and 94: PlanesPlanesWe have developed our D

- Page 95 and 96: PlanesKunz ® PlanesKunz is known f

- Page 97 and 98: PlanesJapanese Planes (Kanna)Japane

- Page 100 and 101: PlanesWestern Wooden Planese.c.e.

- Page 102 and 103: PlanesScraper Blades and ScrapersSc

- Page 104 and 105: Sharpening DevicesBench StonesKing

- Page 106 and 107: Sharpening DevicesaBcShapton ®The

- Page 108 and 109: Sheet Sharpening devicesGrita) Puri

- Page 110 and 111: Sharpening Devicesnatural Japanese

- Page 112 and 113: Sharpening DevicesaB c da DMT ® DI

- Page 114 and 115: Sharpening DevicesSharpening Bestse

- Page 116 and 117: Sharpening DevicesaB TORMEK ® DRIL

- Page 118 and 119: Sharpening Devicesneed practical he

- Page 120 and 121: Sharpening DevicesaBca OIL POT »AB

- Page 122 and 123: Hammers, Nails, Pry BarsJapanese Ha

- Page 124 and 125: Hammers, Nails, Pry Barswww.more-th

- Page 126 and 127: Hammers, Nails, Pry Barsa B cdSoft-

- Page 128 and 129: Hammers, Nails, Pry BarsJapanese na

- Page 130 and 131: Woodturning ToolsWOODTURNING -A HAN

- Page 132 and 133: Woodturning ToolsScrapersCROWN ® M

- Page 134 and 135:

Woodturning ToolsWiedemannWiedemann

- Page 136 and 137:

Woodturning Toolsaa HENRY TAYLOR ®

- Page 138 and 139:

Woodturning ToolsSharpening Devices

- Page 140 and 141:

Woodturning Toolsa 1 2 Ba AxMINSTER

- Page 142 and 143:

Woodturning ToolsPen-turning Access

- Page 144 and 145:

Rasps, FilesHand-Cut RaspsCut by ma

- Page 146 and 147:

Rasps, FilesB c daa hattOri ® raSp

- Page 148 and 149:

Rasps, FilesSuperhard file raspsRob

- Page 150 and 151:

Rasps, Filesa 1 2 3 4 5 6 7 8 B 1 2

- Page 152 and 153:

Rasps, Filesa F.D. ® CHECKERING FI

- Page 154 and 155:

Rasps, FilesHandles and Accessories

- Page 157 and 158:

Measuring and Inspection Instrument

- Page 159 and 160:

Measuring and Inspection Instrument

- Page 161:

Measuring and Inspection Instrument

- Page 164 and 165:

Measuring and Inspection Instrument

- Page 167 and 168:

Scribing andCutting ToolsExact scri

- Page 169 and 170:

Scribing and Cutting Toolsaa KUNz

- Page 171 and 172:

Router Bits | 172Wood Twist Drills

- Page 173 and 174:

Router Bits and Drilling ToolsWood

- Page 175 and 176:

Router Bits and Drilling ToolsaBa C

- Page 177 and 178:

Router Bits and Drilling Toolsa CRO

- Page 179 and 180:

Router Bits and Drilling ToolsBc 1a

- Page 181 and 182:

Screwdriversand PliersTrust them fo

- Page 183 and 184:

Screwdrivers and Pliersaa WERA ® K

- Page 185 and 186:

Screwdrivers and PliersPliersKeiba

- Page 187 and 188:

ClampsBinding together!Solid Steel

- Page 189 and 190:

Clampsa ONE-HAND SPREADER CLAMPS ®

- Page 191 and 192:

Clampsa PONY ® CLAMP FIxTURESLengt

- Page 193 and 194:

Working with method!Tool Sets | 194

- Page 195 and 196:

Workshop Accessories & Toolkitsa JA

- Page 197 and 198:

Workshop Accessories & Toolkitsa UL

- Page 199 and 200:

Workshop Accessories & Toolkitsaa I

- Page 201 and 202:

Workshop Accessories & Toolkitsheue

- Page 203 and 204:

Workshop Accessories & ToolkitscBc

- Page 205 and 206:

Workshop Accessories & ToolkitsWool

- Page 207 and 208:

Leder- und Papierwerkzeuge | Blindt

- Page 209 and 210:

Leather- and Paper-Working Toolswww

- Page 211 and 212:

Leather- and Paper-Working Toolslea

- Page 213 and 214:

Bringing out the beauty of wood!Smo

- Page 215 and 216:

FinishingMicro-Mesh ® abrasive and

- Page 217 and 218:

FinishingSurface Protection and Col

- Page 219 and 220:

FinishingBaa ASUSO ® NL BANGKIRAI,

- Page 221 and 222:

FinishingaBa WOODEN PUTTY KNIFE FOR

- Page 223 and 224:

FinishingGlues and Glue Potstitebon

- Page 225 and 226:

FinishingSheet gluesno. / descripti

- Page 227 and 228:

European Wood | 228A dream come tru

- Page 229 and 230:

MaterialsExotic Wooda EBONYEbony, o

- Page 231 and 232:

MaterialsNuts, Cones and Semifinish

- Page 233 and 234:

Materialsa1a VULCANIzED FIBERVulcan

- Page 235 and 236:

Materialsa1h2d1 2h DEER SKIN LACE,

- Page 237 and 238:

MaterialsOther Animal Materialsaa B

- Page 239 and 240:

The hocho is the soul of the cook«

- Page 241 and 242:

Japanese Kniveschoosing the right k

- Page 243 and 244:

Japanese Knivesa SHIGEFUSA HOCHO KA

- Page 245 and 246:

Japanese KnivesHayashi HochoLight a

- Page 247 and 248:

Japanese Knivesa TANGANRYU HOCHOA p

- Page 249 and 250:

Japanese KnivesSaku hochoThese all-

- Page 251 and 252:

Japanese KnivesInclusive free sharp

- Page 253 and 254:

Japanese KnivesSharp, for all inten

- Page 256 and 257:

Japanese Knivespuristical classicsK

- Page 258 and 259:

Knives for Special ApplicationsKniv

- Page 260 and 261:

Kitchen UtensilsKitchen UtensilsKni

- Page 262 and 263:

Kitchen Utensilspeeler, rasps and a

- Page 264 and 265:

Kitchen Utensilstea Bowls, tea Boxe

- Page 266 and 267:

Kitchen Utensilscast-iron cookwarea

- Page 268 and 269:

Hunting and Outdoor KnivesSaji‘s

- Page 270 and 271:

Hunting and Outdoor KnivesJapanese

- Page 272 and 273:

Hunting and Outdoor Knivesnordic hu

- Page 274 and 275:

Hunting and Outdoor KnivesJapanese

- Page 276 and 277:

Hunting and Outdoor KnivesWestern d

- Page 278 and 279:

Hunting and Outdoor KnivesartO fold

- Page 280 and 281:

Hunting and Outdoor Knivesa MASERIN

- Page 282 and 283:

Blades and Blade Blanksa SWEDISH DA

- Page 284 and 285:

Knife KitsaBa IC CUT ® OUTDOOR KNI

- Page 286 and 287:

Razors and ScissorsTHE FINE ART OF

- Page 288 and 289:

Razors and ScissorsaBa RAzOR WITHGO

- Page 290 and 291:

Razors and ScissorsKlarHigh-quality

- Page 292 and 293:

Razors and ScissorsJapanese tailor

- Page 294 and 295:

Garden ToolsHoes and Clawstwo-hande

- Page 296 and 297:

Garden ToolsShovels, Forks and Rake

- Page 298 and 299:

Garden ToolsOne-Hand Garden ShearsJ

- Page 300 and 301:

Garden Toolslöwe ® prunersThe inv

- Page 302 and 303:

Garden ToolsBall valve ofcentre oil

- Page 304 and 305:

Garden Toolsaa HAND-FORGED HEDGEAND

- Page 306 and 307:

Garden Toolsaa BARNEL ® DOUBLE-EDG

- Page 308 and 309:

Garden Toolsaa JapaneSe teleScOpicp

- Page 310 and 311:

Garden ToolsaBca SCYTHE SICKLEThis

- Page 312 and 313:

Garden Toolsaa CONCAVE BRANCH CUTTE

- Page 314 and 315:

Garden Toolsa JAPANESE RUBBER BOOTS

- Page 316 and 317:

Arts and CraftsWooden ObjectsUrushi

- Page 318 and 319:

Arts and CraftsBamboo productsBambo

- Page 320 and 321:

Arts and Craftsaa LEIHO STOOLA uniq

- Page 322 and 323:

Arts and Craftsaa »INDEN-YA« POCK

- Page 324 and 325:

BooksThe more intensively one studi

- Page 326 and 327:

BooksPRACTICAL DESGINThis book offe

- Page 328 and 329:

BooksBANDSäGEN - EINRICHTEN,BEHERR

- Page 330 and 331:

BooksTHE ART OF HANDSEWING LEATHERA

- Page 332 and 333:

indexIndexaAbrasive and polishing c

- Page 334 and 335:

indexHook tool (woodturning) 134Hor

- Page 336 and 337:

indexSickle hoe 294, 309Sickle knif

- Page 338 and 339:

MORE THAN JUST One TOOL CATALOGUEal

- Page 340:

Order Hotline:Telephone: +49-(0)991