issue-50_v1

issue-50_v1

issue-50_v1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

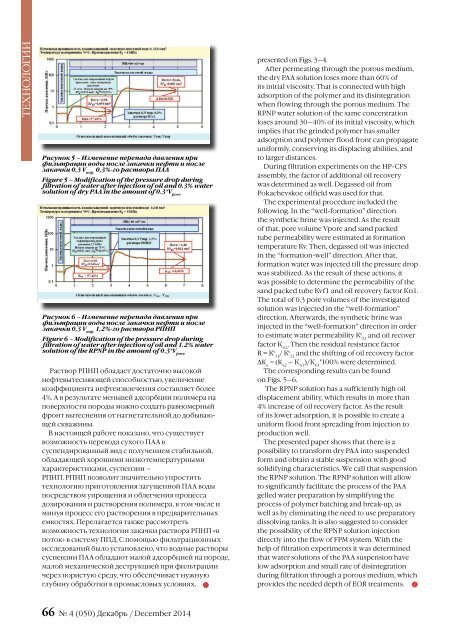

технологииРисунок 5 – Изменение перепада давления прифильтрации воды после закачки нефти и послезакачки 0,3 V пор.0,3%-го раствора ПААFigure 5 – Modification of the pressure drop duringfiltration of water after injection of oil and 0.3% watersolution of dry PAA in the amount of 0.3*V poreРисунок 6 – Изменение перепада давления прифильтрации воды после закачки нефти и послезакачки 0,3 V пор.1,2%-го раствора РПНПFigure 6 – Modification of the pressure drop duringfiltration of water after injection of oil and 1.2% watersolution of the RPNP in the amount of 0.3*V poreРаствор РПНП обладает достаточно высокойнефтевытесняющей способностью, увеличениекоэффициента нефтеизвлечения составляет более4%. А в результате меньшей адсорбции полимера наповерхности породы можно создать равномерныйфронт вытеснения от нагнетательной до добывающейскважины.В настоящей работе показано, что существуетвозможность перевода сухого ПАА всуспендированный вид с получением стабильной,обладающей хорошими низкотемпературнымихарактеристиками, суспензии –РПНП. РПНП позволит значительно упроститьтехнологию приготовления загущенной ПАА водыпосредством упрощения и облегчения процессадозирования и растворения полимера, в том числе иминуя процесс его растворения в предварительныхемкостях. Перелагается также рассмотретьвозможность технологии закачки раствора РПНП «впоток» в систему ППД. С помощью фильтрационныхисследований было установлено, что водные растворысуспензии ПАА обладают малой адсорбцией на породе,малой механической деструкцией при фильтрациичерез пористую среду, что обеспечивает нужнуюглубину обработки в промысловых условиях.presented on Figs. 3–4.After permeating through the porous medium,the dry PAA solution loses more than 60% ofits initial viscosity. That is connected with highadsorption of the polymer and its disintegrationwhen flowing through the porous medium. TheRPNP water solution of the same concentrationloses around 30–40% of its initial viscosity, whichimplies that the grinded polymer has smalleradsorption and polymer flood front can propagateuniformly, conserving its displacing abilities, andto larger distances.During filtration experiments on the HP-CFSassembly, the factor of additional oil recoverywas determined as well. Degassed oil fromPokachevskoe oilfield was used for that.The experimental procedure included thefollowing. In the “well-formation” directionthe synthetic brine was injected. As the resultof that, pore volume Vpore and sand packedtube permeability were estimated at formationtemperature Кv. Then, degassed oil was injectedin the “formation-well” direction. After that,formation water was injected till the pressure dropwas stabilized. As the result of these actions, itwas possible to determine the permeability of thesand packed tube Кvf1 and oil recovery factor Кn1.The total of 0.3 pore volumes of the investigatedsolution was injected in the “well-formation”direction. Afterwards, the synthetic brine wasinjected in the “well-formation” direction in orderto estimate water permeability К v and oil recoverf2factor К n2. Then the residual resistance factorR = К v / f1 Кv and the shifting of oil recovery factorf2ΔК n= (К n2– К n1)/К n1*100% were determined.The corresponding results can be foundon Figs. 5–6.The RPNP solution has a sufficiently high oildisplacement ability, which results in more than4% increase of oil recovery factor. As the resultof its lower adsorption, it is possible to create auniform flood front spreading from injection toproduction well.The presented paper shows that there is apossibility to transform dry PAA into suspendedform and obtain a stable suspension with goodsolidifying characteristics. We call that suspensionthe RPNP solution. The RPNP solution will allowto significantly facilitate the process of the PAAgelled water preparation by simplifying theprocess of polymer batching and break-up, aswell as by eliminating the need to use preparatorydissolving tanks. It is also suggested to considerthe possibility of the RPNP solution injectiondirectly into the flow of FPM system. With thehelp of filtration experiments it was determinedthat water solutions of the PAA suspension havelow adsorption and small rate of disintegrationduring filtration through a porous medium, whichprovides the needed depth of EOR treatments.66 № 4 (0<strong>50</strong>) Декабрь / December 2014