- Page 1 and 2:

GK-1 CATALOG-HANDBOOK • NINTH EDI

- Page 3 and 4:

TZGPICTORIAL PRODUCT INDEXSDGAZ335S

- Page 6:

ALPHANUMERIC PRODUCT INDEXProductSe

- Page 17 and 18:

AZ17 TECHNICAL DATAMECHANICAL SPECI

- Page 19 and 20:

SERIES AZ17ziIndividually-Coded Mov

- Page 21 and 22:

AZ17zi TECHNICAL DATAMECHANICAL SPE

- Page 23 and 24:

SERIES AZ15/16DescriptionThe Series

- Page 25 and 26:

AZ15/16 TECHNICAL DATAMECHANICAL SP

- Page 27 and 28:

AZ15/16 ACTUATOR KEY SPECIFICATIONS

- Page 29 and 30:

SERIES AZ16ziIndividually-Coded Mov

- Page 31 and 32:

AZ16zi TECHNICAL DATAHousingActuato

- Page 33 and 34:

SERIES AZ 200Pulse-Echo BasedNon-Co

- Page 35 and 36:

SERIES TZGDescriptionThe Series TZG

- Page 37 and 38:

TZG TECHNICAL DATAMECHANICAL SPECIF

- Page 39 and 40:

SERIES SDGDescription®The Series S

- Page 41 and 42:

SDG TECHNICAL DATAMECHANICAL SPECIF

- Page 43 and 44:

SERIES AZ335Tamper-Resistant Movabl

- Page 45 and 46:

AZ335 INDIVIDUALLY-CODED ACTUATOR K

- Page 47 and 48:

SERIES SHGVCable-less Keyed Mechani

- Page 49 and 50:

SERIES AZ415DescriptionThe AZ415 Se

- Page 51 and 52:

AZ415 TECHNICAL DATAACTUATOR KEY DI

- Page 53 and 54:

42SaferbyDesign

- Page 55 and 56:

SERIES AZM170DescriptionThe AZM170

- Page 57 and 58:

AZM170 TECHNICAL DATAMECHANICAL SPE

- Page 59 and 60:

48AZM170 TECHNICAL DATADIMENSIONS10

- Page 61 and 62:

AZM161Solenoid-Latching Safety Inte

- Page 63 and 64:

AZM161 TECHNICAL DATAMECHANICAL SPE

- Page 65 and 66:

SERIES AZM 200New!Pulse-Echo BasedN

- Page 67 and 68:

SERIES MZM 100Non-Contact Magnetic-

- Page 69 and 70:

SERIES TZF/TZMDescriptionThe TZF/TZ

- Page 71 and 72:

SERIES TZF/TZM TECHNICAL DATAMECHAN

- Page 73 and 74:

SERIES TKF/TKMDescription®The TKF/

- Page 75 and 76:

SERIES TKF/TKM TECHNICAL DATAMECHAN

- Page 77 and 78:

SERIES TZKDescriptionThe TZK Series

- Page 79 and 80:

SERIES TZK TECHNICAL DATAMECHANICAL

- Page 81 and 82:

SERIES AZM415DescriptionThe AZM415

- Page 83 and 84:

AZM415 TECHNICAL DATAWIRING SCHEMAT

- Page 85 and 86:

AZS 2305Fail-To-Safe TimerSafety Ca

- Page 87 and 88:

FWS 1205Fail-To-Safe Standstill Mon

- Page 89 and 90:

FWS 2505Fail-To-Safe Standstill Mon

- Page 91 and 92:

80SaferbyDesign

- Page 93 and 94:

SERIES STSSafety Guard Door-Handle

- Page 95 and 96:

SERIES STSTO ORDER COMPLETE STS DOO

- Page 97 and 98:

SERIES STS ACCESSORIESLockout Acces

- Page 99 and 100:

SERIES B25Safety Door Handle System

- Page 101 and 102:

SERIES TG-1Door Handle For Use With

- Page 103 and 104:

SERIES ZSD3-Position Hand-Held Enab

- Page 105 and 106:

SERIES GFSSafety Foot Switch®Featu

- Page 107 and 108:

GFS SERIES TECHNICAL DATAMECHANICAL

- Page 109 and 110:

SERIES SEPK(G)New!2-Hand Control Co

- Page 111 and 112:

Series TFA/TFIGuard Alignment AidNe

- Page 113 and 114:

ZS71Emergency Cable-Pull Switch (Me

- Page 115 and 116:

ZS71 TECHNICAL DATAMECHANICAL SPECI

- Page 117 and 118:

ZS73 Heavy-Duty Emergency Cable-Pul

- Page 119 and 120:

ZS73 TECHNICAL DATAMECHANICAL SPECI

- Page 121 and 122:

ZS75 Heavy-Duty Emergency Cable-Pul

- Page 123 and 124:

ZS75 TECHNICAL DATAMECHANICAL SPECI

- Page 125 and 126:

Series ZS441 Heavy-Duty Emergency C

- Page 127 and 128:

ZS441 TECHNICAL DATAMECHANICAL SPEC

- Page 129 and 130:

ZS75S BidirectionalHeavy-Duty Bidir

- Page 131 and 132:

ZS75S BIDIRECTIONAL TECHNICAL DATAR

- Page 133 and 134:

ZS80 Emergency Cable-Pull Switch (M

- Page 135 and 136:

ZS80 TECHNICAL DATAMECHANICAL SPECI

- Page 137 and 138:

S900Cable-Pull Switch Wire Tensione

- Page 139 and 140:

128SaferbyDesign

- Page 141 and 142:

SERIES BNS250Coded-Magnet SensorsFe

- Page 143 and 144:

SERIES BNS260Coded-Magnet SensorsFe

- Page 145 and 146:

SERIES BNS33 & BNS33SCoded-Magnet S

- Page 147 and 148:

BNS33 TECHNICAL DATAMECHANICAL SPEC

- Page 149 and 150:

SERIES BNS33SStainless Steel Coded-

- Page 151 and 152:

SERIES BNS36Coded-Magnet SensorsNew

- Page 153 and 154:

SERIES BNS303Coded-Magnet SensorsFe

- Page 155 and 156:

SERIES BNS30 & BNS300Coded-Magnet S

- Page 157 and 158:

SERIES BNS333Coded-Magnet Sensors w

- Page 159 and 160:

SERIES BNS16Coded-Magnet SensorsFea

- Page 161 and 162:

SERIES BZ16Dual-Channel Non-Contact

- Page 163 and 164:

SERIES BNS-B20New!Coded-Magnet Sens

- Page 165 and 166:

SERIES CSS 180New!Pulse-Echo BasedN

- Page 167 and 168:

SERIES CSS 34Pulse-Echo Based Compa

- Page 169 and 170:

158SaferbyDesign

- Page 171 and 172:

AES 1102/AES 1112BNS Compatible Con

- Page 173 and 174:

AES 1135/AES 1165BNS Compatible Saf

- Page 175 and 176:

AES 1235/AES 1265BNS Compatible Saf

- Page 177 and 178:

AES 2135BNS Compatible Safety Contr

- Page 179 and 180:

AES 2335BNS Compatible Safety Contr

- Page 181 and 182:

AES 1337BNS Compatible Safety Contr

- Page 183 and 184:

SERIES SRB 211 ANBNS Compatible Saf

- Page 185 and 186:

AES 2285/SRB 207 AN BNS Compatible

- Page 187 and 188:

176SaferbyDesign

- Page 189 and 190:

SERIES AZ 200Pulse-Echo BasedNon-Co

- Page 191 and 192:

SERIES AZ 200 TECHNICAL DATAMECHANI

- Page 193 and 194:

SERIES AZ 200 WIRING EXAMPLESWIRING

- Page 195 and 196:

SERIES AZM 200New!Pulse-Echo BasedN

- Page 197 and 198:

SERIES AZM 200 TECHNICAL DATAMECHAN

- Page 199 and 200:

SERIES AZM 200 WIRING EXAMPLESWIRIN

- Page 201 and 202:

SERIES MZM 100Non-Contact Magnetic-

- Page 203 and 204:

SERIES MZM 100 DIAGNOSTICSFunction

- Page 205 and 206:

SERIES CSS 180New!Pulse-Echo BasedN

- Page 207 and 208:

SERIES CSS 180 TECHNICAL DATASWITCH

- Page 209 and 210:

SERIES CSS 180 WIRING EXAMPLE 2Seri

- Page 211 and 212:

SERIES CSS 34Pulse-Echo Based Compa

- Page 213 and 214:

SERIES CSS 34 TECHNICAL DATASWITCHI

- Page 215 and 216:

SERIES CSS 34 WIRING EXAMPLE 2Wirin

- Page 217 and 218:

COMPATIBLE PULSE-ECHO SAFETY CONTRO

- Page 219 and 220:

208SaferbyDesign

- Page 221 and 222:

SERIES TESFDescriptionThe TESF Seri

- Page 223 and 224:

SERIES TESF TECHNICAL DATADIMENSION

- Page 225 and 226:

Series TESZHinged Safety Interlock

- Page 227 and 228:

Series ES95 SBHinged Safety Interlo

- Page 229 and 230:

Series TVS335Hinged Safety Interloc

- Page 231 and 232:

Series T.C 235/236Hinged Safety Int

- Page 233 and 234:

T.C 235 TECHNICAL DATAContact funct

- Page 235 and 236:

T.C 236 TECHNICAL DATAContact funct

- Page 237 and 238:

226SaferbyDesign

- Page 239 and 240:

SERIES Z/T235Safety-Rated, Positive

- Page 241 and 242:

Z/T235 TECHNICAL DATAContact functi

- Page 243 and 244:

Z/T235 TECHNICAL DATAContact functi

- Page 245 and 246:

Z/T235 TECHNICAL DATAContact functi

- Page 247 and 248:

SERIES Z/T236Safety-Rated, Positive

- Page 249 and 250:

Z/T236 TECHNICAL DATAContact functi

- Page 251 and 252:

Z/T236 TECHNICAL DATAContact functi

- Page 253 and 254:

Z/T236 TECHNICAL DATAContact functi

- Page 255 and 256:

SERIES Z/T335Heavy-Duty Safety-Rate

- Page 257 and 258:

Z/T335 TECHNICAL DATAContact functi

- Page 259 and 260:

Z/T335 TECHNICAL DATAContact functi

- Page 261 and 262:

SERIES Z/T336Heavy-Duty Safety-Rate

- Page 263 and 264:

Z/T336 TECHNICAL DATAContact functi

- Page 265 and 266:

Z/T336 TECHNICAL DATAContact functi

- Page 267 and 268:

SERIES Z332Heavy-Duty Safety-Rated,

- Page 269 and 270:

Z332 TECHNICAL DATAContact function

- Page 271 and 272:

SERIES C50Compact, Safety-Rated,Pos

- Page 273 and 274:

262SaferbyDesign

- Page 275 and 276:

264SaferbyDesign

- Page 277 and 278:

Introduction - Optoelectronic safet

- Page 279 and 280:

Design and operating principleOptoe

- Page 281 and 282:

ApplicationSafety distanceEN 999Saf

- Page 283 and 284:

Modes of operation and functionsMas

- Page 285 and 286:

274SaferbyDesign

- Page 287 and 288:

OSSD FAILCOSSD FAILCSafety light cu

- Page 289 and 290:

OSSD FAILCOSSD FAILCSafety light cu

- Page 291 and 292:

Safety light curtains and safety li

- Page 293 and 294:

OSSD FAILCOSSD FAILCSafety light cu

- Page 295 and 296:

Safety light grid (retro-reflector)

- Page 297 and 298:

Safety light curtains and safety li

- Page 299 and 300:

CCSafety light curtains and safety

- Page 301 and 302:

Safety light grids with integrated

- Page 303 and 304:

==Accessories for safety light curt

- Page 305 and 306:

294SaferbyDesign

- Page 307 and 308:

Safety monitoring modules for optoe

- Page 309 and 310:

Safety monitoring modules for optoe

- Page 311 and 312:

300SaferbyDesign

- Page 313 and 314:

Safety light barriersSLB 2002030,8

- Page 315 and 316:

Safety light barriersSLB 200-C• T

- Page 317 and 318:

Safety light barriersSLB 400-C• T

- Page 319 and 320:

Safety light barriers accessories S

- Page 321 and 322:

SERIES SMS 3Safety Pressure MatsFea

- Page 323 and 324:

SERIES SMS 3 COMPATIBLE SAFETY CONT

- Page 325 and 326:

OPTIONAL JUNCTION BOX FOR MULTIPLE

- Page 327 and 328:

316SaferbyDesign

- Page 329 and 330:

SERIES SEOptical Safety Edges/Bumpe

- Page 331 and 332:

SERIES SE TECHNICAL DATAAluminum Mo

- Page 333 and 334:

SERIES SE TECHNICAL DATATransmitter

- Page 335 and 336:

SERIES SE TECHNICAL DATASE 304CElec

- Page 337 and 338:

326SaferbyDesign

- Page 339 and 340:

ModelSRB 201 ZHSRB 301 HC/ROperatin

- Page 341 and 342:

SERIES SRB 201 ZH &SRB 301 HC/RTwo-

- Page 343 and 344:

SERIES SRB 202 MSLMuting Safety Con

- Page 345 and 346:

SERIES SRB 206 &SRB 206 SQGeneral P

- Page 347 and 348:

SERIES SRB 211 ANGeneral Purpose Sa

- Page 349 and 350:

SERIES SRB 211 STGeneral Purpose Sa

- Page 351 and 352:

SERIES SRB 301 LC &General Purpose

- Page 353 and 354:

SERIES SRB 301 MCGeneral Purpose Sa

- Page 355 and 356:

SERIES SRB 301 STSERIES SRB 301 ST

- Page 357 and 358:

SERIES SRB 324 STGeneral Purpose Sa

- Page 359 and 360:

SERIES SRB 202 C &SRB 400 CDifferen

- Page 361 and 362:

SERIES SRB 401 LCGeneral Purpose Sa

- Page 363 and 364:

SERIES SRB 402 EM &SRB 401 EM-115VS

- Page 365 and 366:

SERIES SRB 504 STGeneral Purpose Sa

- Page 367 and 368:

SERIES PROTECT-IE-02 &PROTECT-IE-11

- Page 369 and 370:

358SaferbyDesign

- Page 371 and 372:

360

- Page 373 and 374: I. Man-Machine SafeguardingPrincipl

- Page 375 and 376: 364FIGURE 2Conventional versus Posi

- Page 377 and 378: 7What is meant by a “positive lin

- Page 379 and 380: 10What are “self-checking,” “

- Page 381 and 382: 15Why are safety interlock switches

- Page 383 and 384: II. Control Reliability19What is me

- Page 385 and 386: 22What are “redundant” logic ci

- Page 387 and 388: III. Risk Assessment26What is “ri

- Page 389 and 390: 29Which of these risk category safe

- Page 391 and 392: IV. Safety Standards,Marking and th

- Page 393 and 394: 38To what type machines does the Eu

- Page 395 and 396: 42Why should safety controllers be

- Page 397 and 398: VI. Applications and Solutions46Wha

- Page 399 and 400: Frequently Asked QuestionsSelection

- Page 401 and 402: I. Selection & Application Characte

- Page 403 and 404: 5What light curtain resolutions are

- Page 405 and 406: 10What is “muting”?“Muting”

- Page 407 and 408: 14What questions might I ask to bet

- Page 409 and 410: 17How do I calculate the correct

- Page 411 and 412: 19After doing the “safety distanc

- Page 413 and 414: 24Must light curtains only be used

- Page 415 and 416: IV. Standards & Certifications30Doe

- Page 417 and 418: Blanking (Fixed Blanking):“Fixed

- Page 419 and 420: OSSD:“OSSD” is the abbreviation

- Page 421 and 422: SELECTED MACHINE SAFEGUARDINGTERMIN

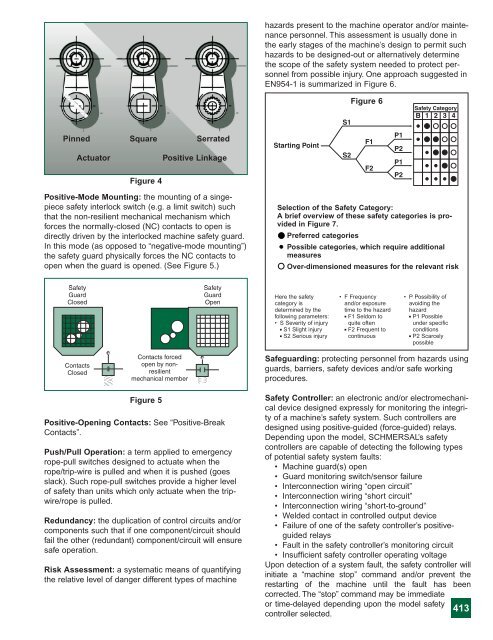

- Page 423: Point-of-Operation: the area(s) of

- Page 427 and 428: prEN1760-1 Safety of Machinery - Pr

- Page 429 and 430: 418SaferbyDesign

- Page 431 and 432: TypeDesignation420123NEMA, UL, CSA

- Page 433 and 434: GENERAL TERMS & CONDITIONS OF SALEO

- Page 435: 424NOTES