MY1 Mechanically Jointed Rodless Cylinder

MY1 Mechanically Jointed Rodless Cylinder

MY1 Mechanically Jointed Rodless Cylinder

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

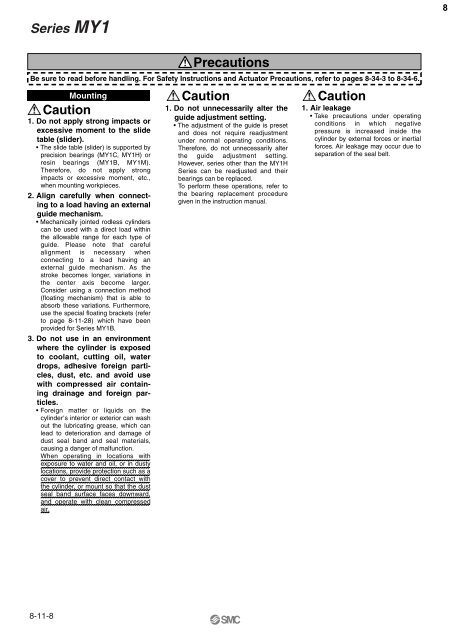

Series <strong>MY1</strong>8PrecautionsBe sure to read before handling. For Safety Instructions and Actuator Precautions, refer to pages 8-34-3 to 8-34-6.MountingCaution1. Do not apply strong impacts orexcessive moment to the slidetable (slider).• The slide table (slider) is supported byprecision bearings (<strong>MY1</strong>C, <strong>MY1</strong>H) orresin bearings (<strong>MY1</strong>B, <strong>MY1</strong>M).Therefore, do not apply strongimpacts or excessive moment, etc.,when mounting workpieces.2. Align carefully when connectingto a load having an externalguide mechanism.• <strong>Mechanically</strong> jointed rodless cylinderscan be used with a direct load withinthe allowable range for each type ofguide. Please note that carefulalignment is necessary whenconnecting to a load having anexternal guide mechanism. As thestroke becomes longer, variations inthe center axis become larger.Consider using a connection method(floating mechanism) that is able toabsorb these variations. Furthermore,use the special floating brackets (referto page 8-11-28) which have beenprovided for Series <strong>MY1</strong>B.3. Do not use in an environmentwhere the cylinder is exposedto coolant, cutting oil, waterdrops, adhesive foreign particles,dust, etc. and avoid usewith compressed air containingdrainage and foreign particles.•Foreign matter or liquids on thecylinder , s interior or exterior can washout the lubricating grease, which canlead to deterioration and damage ofdust seal band and seal materials,causing a danger of malfunction.When operating in locations withexposure to water and oil, or in dustylocations, provide protection such as acover to prevent direct contact withthe cylinder, or mount so that the dustseal band surface faces downward,and operate with clean compressedair.Caution1. Do not unnecessarily alter theguide adjustment setting.• The adjustment of the guide is presetand does not require readjustmentunder normal operating conditions.Therefore, do not unnecessarily alterthe guide adjustment setting.However, series other than the <strong>MY1</strong>HSeries can be readjusted and theirbearings can be replaced.To perform these operations, refer tothe bearing replacement proceduregiven in the instruction manual.Caution1. Air leakage•Take precautions under operatingconditions in which negativepressure is increased inside thecylinder by external forces or inertialforces. Air leakage may occur due toseparation of the seal belt.8-11-8