Grundfos Alldos DDI-209 User Manual - Industry Surplus Australia

Grundfos Alldos DDI-209 User Manual - Industry Surplus Australia

Grundfos Alldos DDI-209 User Manual - Industry Surplus Australia

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

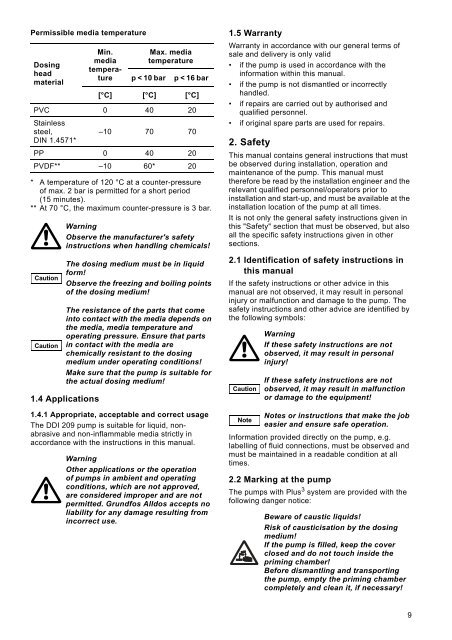

Permissible media temperatureDosingheadmaterial* A temperature of 120 °C at a counter-pressureof max. 2 bar is permitted for a short period(15 minutes).** At 70 °C, the maximum counter-pressure is 3 bar.1.4 ApplicationsMin.mediatemperatureMax. mediatemperaturep < 10 barp < 16 bar[°C] [°C] [°C]PVC 0 40 20Stainlesssteel,–10 70 70DIN 1.4571*PP 0 40 20PVDF** –10 60* 20CautionCautionWarningObserve the manufacturer's safetyinstructions when handling chemicals!The dosing medium must be in liquidform!Observe the freezing and boiling pointsof the dosing medium!The resistance of the parts that comeinto contact with the media depends onthe media, media temperature andoperating pressure. Ensure that partsin contact with the media arechemically resistant to the dosingmedium under operating conditions!Make sure that the pump is suitable forthe actual dosing medium!1.4.1 Appropriate, acceptable and correct usageThe <strong>DDI</strong> <strong>209</strong> pump is suitable for liquid, nonabrasiveand non-inflammable media strictly inaccordance with the instructions in this manual.WarningOther applications or the operationof pumps in ambient and operatingconditions, which are not approved,are considered improper and are notpermitted. <strong>Grundfos</strong> <strong>Alldos</strong> accepts noliability for any damage resulting fromincorrect use.1.5 WarrantyWarranty in accordance with our general terms ofsale and delivery is only valid• if the pump is used in accordance with theinformation within this manual.• if the pump is not dismantled or incorrectlyhandled.• if repairs are carried out by authorised andqualified personnel.• if original spare parts are used for repairs.2. SafetyThis manual contains general instructions that mustbe observed during installation, operation andmaintenance of the pump. This manual musttherefore be read by the installation engineer and therelevant qualified personnel/operators prior toinstallation and start-up, and must be available at theinstallation location of the pump at all times.It is not only the general safety instructions given inthis "Safety" section that must be observed, but alsoall the specific safety instructions given in othersections.2.1 Identification of safety instructions inthis manualIf the safety instructions or other advice in thismanual are not observed, it may result in personalinjury or malfunction and damage to the pump. Thesafety instructions and other advice are identified bythe following symbols:CautionNoteWarningIf these safety instructions are notobserved, it may result in personalinjury!If these safety instructions are notobserved, it may result in malfunctionor damage to the equipment!Notes or instructions that make the jobeasier and ensure safe operation.Information provided directly on the pump, e.g.labelling of fluid connections, must be observed andmust be maintained in a readable condition at alltimes.2.2 Marking at the pumpThe pumps with Plus 3 system are provided with thefollowing danger notice:Beware of caustic liquids!Risk of causticisation by the dosingmedium!If the pump is filled, keep the coverclosed and do not touch inside thepriming chamber!Before dismantling and transportingthe pump, empty the priming chambercompletely and clean it, if necessary!9