- Page 1 and 2:

PowerTech4.5 L and 6.8 LNon-Certifi

- Page 3 and 4:

Introduction• PE4045TF151• PE40

- Page 5 and 6:

IntroductionPOWERTECH ® 4.5 L Engi

- Page 7 and 8:

ContentsPagePageRecord Keeping Inst

- Page 9 and 10:

Record KeepingPOWERTECH ® Medallio

- Page 11 and 12:

Record KeepingEngine Option CodesEn

- Page 13 and 14:

Record KeepingRecord Fuel Injection

- Page 15 and 16:

SafetyReplace Safety SignsReplace m

- Page 17 and 18:

SafetyService Machines SafelyTie lo

- Page 19 and 20:

SafetyPractice Safe MaintenanceUnde

- Page 21 and 22:

SafetyRemove Paint Before Welding o

- Page 23 and 24:

SafetyAvoid Harmful Asbestos DustAv

- Page 25 and 26:

SafetyProtect Against High Pressure

- Page 27 and 28:

Fuels, Lubricants, and CoolantDiese

- Page 29 and 30:

Fuels, Lubricants, and CoolantBio-D

- Page 31 and 32:

Fuels, Lubricants, and CoolantMinim

- Page 33 and 34:

Fuels, Lubricants, and CoolantDiese

- Page 35 and 36:

Fuels, Lubricants, and CoolantOILSC

- Page 37 and 38:

Fuels, Lubricants, and CoolantGreas

- Page 39 and 40:

Fuels, Lubricants, and CoolantWater

- Page 41 and 42:

Fuels, Lubricants, and CoolantEthyl

- Page 43 and 44:

Fuels, Lubricants, and CoolantEthyl

- Page 45 and 46:

Engine Operating GuidelinesInstrume

- Page 47 and 48:

Engine Operating GuidelinesThe rese

- Page 49 and 50:

Engine Operating GuidelinesG—Batt

- Page 51 and 52: Engine Operating GuidelinesIMPORTAN

- Page 53 and 54: Engine Operating GuidelinesAuxiliar

- Page 55 and 56: Engine Operating GuidelinesNOTE: El

- Page 57 and 58: Engine Operating GuidelinesNormal E

- Page 59 and 60: Engine Operating GuidelinesChanging

- Page 61 and 62: Engine Operating GuidelinesUsing a

- Page 63 and 64: Lubrication and MaintenanceObserve

- Page 65 and 66: Lubrication and MaintenanceCheck Ai

- Page 67 and 68: Lubrication and MaintenanceReplace

- Page 69 and 70: Lubrication & Maintenance/DailyCAUT

- Page 71 and 72: Lubrication & Maintenance/Daily4. I

- Page 73 and 74: Lubrication & Maintenance/250 Hour/

- Page 75 and 76: Lubrication & Maintenance/250 Hour/

- Page 77 and 78: Lubrication & Maintenance/250 Hour/

- Page 79 and 80: Lubrication & Maintenance/250 Hour/

- Page 81 and 82: Lubrication & Maintenance/500 Hour/

- Page 83 and 84: Lubrication & Maintenance/500 Hour/

- Page 85 and 86: Lubrication & Maintenance/500 Hour/

- Page 87 and 88: Lubrication & Maintenance/500 Hour/

- Page 89 and 90: Lubrication & Maintenance/500 Hour/

- Page 91 and 92: Lubrication & Maintenance/500 Hour/

- Page 93 and 94: Lubrication & Maintenance/500 Hour/

- Page 95 and 96: Lubrication & Maint./2000 Hour/24 M

- Page 97 and 98: Lubrication & Maint./2000 Hour/24 M

- Page 99 and 100: Lubrication & Maint./2000 Hour/24 M

- Page 101: Lubrication & Maint./2000 Hour/24 M

- Page 105 and 106: Lubrication & Maint./2000 Hour/24 M

- Page 107 and 108: Service as RequiredAdding CoolantCA

- Page 109 and 110: Service as RequiredReplacing Axial

- Page 111 and 112: Service as RequiredReplacing Radial

- Page 113 and 114: Service as RequiredReplacing Fan an

- Page 115 and 116: Service as RequiredChecking Air Com

- Page 117 and 118: Service as RequiredIMPORTANT: Do no

- Page 119 and 120: Service as RequiredOn DENSO and Mot

- Page 121 and 122: Troubleshooting50-2 110306PN=121

- Page 123 and 124: TroubleshootingWiring Diagram (Stan

- Page 125 and 126: TroubleshootingEngine Wiring Diagra

- Page 127 and 128: TroubleshootingSymptom Problem Solu

- Page 129 and 130: TroubleshootingSymptom Problem Solu

- Page 131 and 132: TroubleshootingSymptom Problem Solu

- Page 133 and 134: StorageEngine Storage Guidelines1.

- Page 135 and 136: Storage15. Store the engine in a dr

- Page 137 and 138: SpecificationsGeneral OEM Engine Sp

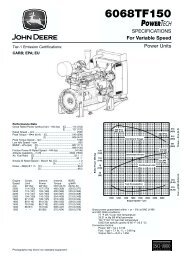

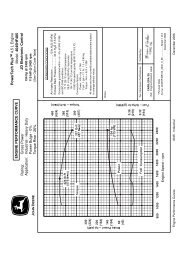

- Page 139 and 140: SpecificationsPOWER RATINGS ON DYNA

- Page 141 and 142: SpecificationsPOWER RATINGS ON DYNA

- Page 143 and 144: SpecificationsPOWER RATINGS ON DYNA

- Page 145 and 146: SpecificationsPOWER RATINGS ON DYNA

- Page 147 and 148: SpecificationsEngine Model Oil Pan

- Page 149 and 150: SpecificationsEngine Crankcase Oil

- Page 151 and 152: SpecificationsMetric Bolt and Screw

- Page 153 and 154:

Lubrication and Maintenance Records

- Page 155 and 156:

Lubrication and Maintenance Records

- Page 157 and 158:

Emission System WarrantyU.S. EPA Em

- Page 159 and 160:

John Deere Service Literature Avail

- Page 161 and 162:

IndexPagePageA Check ..............

- Page 163 and 164:

IndexPagePageEngine serial number .