RMP Underground Conduit System Installation Guide (Procedure 242)

RMP Underground Conduit System Installation Guide (Procedure 242)

RMP Underground Conduit System Installation Guide (Procedure 242)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

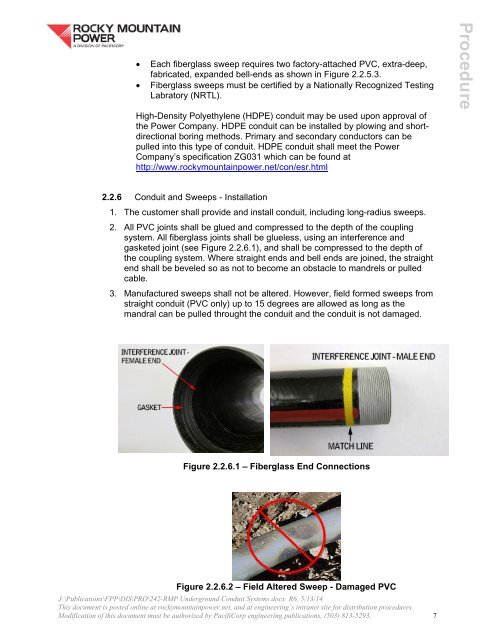

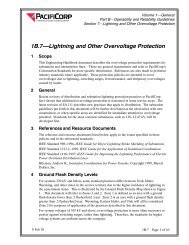

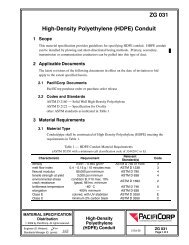

• Each fiberglass sweep requires two factory-attached PVC, extra-deep,fabricated, expanded bell-ends as shown in Figure 2.2.5.3.• Fiberglass sweeps must be certified by a Nationally Recognized TestingLabratory (NRTL).High-Density Polyethylene (HDPE) conduit may be used upon approval ofthe Power Company. HDPE conduit can be installed by plowing and shortdirectionalboring methods. Primary and secondary conductors can bepulled into this type of conduit. HDPE conduit shall meet the PowerCompany’s specification ZG031 which can be found athttp://www.rockymountainpower.net/con/esr.html<strong>Procedure</strong>2.2.6 <strong>Conduit</strong> and Sweeps - <strong>Installation</strong>1. The customer shall provide and install conduit, including long-radius sweeps.2. All PVC joints shall be glued and compressed to the depth of the couplingsystem. All fiberglass joints shall be glueless, using an interference andgasketed joint (see Figure 2.2.6.1), and shall be compressed to the depth ofthe coupling system. Where straight ends and bell ends are joined, the straightend shall be beveled so as not to become an obstacle to mandrels or pulledcable.3. Manufactured sweeps shall not be altered. However, field formed sweeps fromstraight conduit (PVC only) up to 15 degrees are allowed as long as themandral can be pulled throught the conduit and the conduit is not damaged.Figure 2.2.6.1 – Fiberglass End ConnectionsFigure 2.2.6.2 – Field Altered Sweep - Damaged PVCJ:\Publications\FPP\DIS\PRO\<strong>242</strong>-<strong>RMP</strong> <strong>Underground</strong> <strong>Conduit</strong> <strong>System</strong>s.docx R6, 5/13/14This document is posted online at rockymountainpower.net, and at engineering’s intranet site for distribution procedures.Modification of this document must be authorized by PacifiCorp engineering publications, (503) 813-5293. 7