You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The formation of yarns is the next major step in the<br />

development of textile products.<br />

The simple process of making yarn predates recorded<br />

history. Cave dwellers used hair fiber from animals that<br />

were twisted into coarse yarn for ropes and nets. Eventually<br />

they refined their techniques to make yarn capable<br />

of being intertwined to produce crude fabrics.<br />

While seemingly unimportant, this invention,<br />

along with the inventions of fire and the wheel, is considered<br />

a major milestone of the world’s civilization. The<br />

ability to create a yarn, and to subsequently interlace<br />

the yarn (weaving) freed primitive humans to leave<br />

their caves in an expanded search for food, and eventually<br />

to migrate to other regions.<br />

The invention of spinning was so profound and yet<br />

so simple that the principle of making yarn, by twisting<br />

fiber while simultaneously pulling or drawing it out, has<br />

remained unchanged throughout the ages and continues<br />

to this day.<br />

Yarns are by definition groups of fibers twisted<br />

together to form a continuous strand. All textile fabrics,<br />

except for a few, such as felt (p. 153) and nonwoven<br />

fabrics (p. 148), are produced from yarns. The yarns are<br />

interlaced (woven), interlooped (knitted), or combined<br />

in other ways to form a textile fabric. There are many<br />

types of yarns, some lustrous, some dull, some smooth,<br />

some rough, some thinner than human hair, some thick<br />

and bulky. Two fabrics each made from the same fiber<br />

(e.g., polyester) and each woven in the same weave (e.g.,<br />

plain weave; p. 97) may be substantially different from<br />

one another in appearance, durability, and cleanability<br />

due to the yarn differences in each of the fabrics.<br />

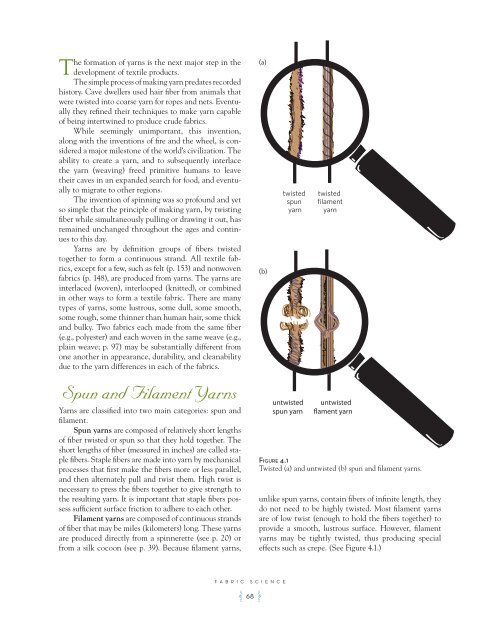

Spun and Filament Yarns<br />

Yarns are classified into two main categories: spun and<br />

filament.<br />

Spun yarns are composed of relatively short lengths<br />

of fiber twisted or spun so that they hold together. The<br />

short lengths of fiber (measured in inches) are called staple<br />

fibers. Staple fibers are made into yarn by mechanical<br />

processes that first make the fibers more or less parallel,<br />

and then alternately pull and twist them. High twist is<br />

necessary to press the fibers together to give strength to<br />

the resulting yarn. It is important that staple fibers possess<br />

sufficient surface friction to adhere to each other.<br />

Filament yarns are composed of continuous strands<br />

of fiber that may be miles (kilometers) long. These yarns<br />

are produced directly from a spinnerette (see p. 20) or<br />

from a silk cocoon (see p. 39). Because filament yarns,<br />

FABRIC SCIENCE<br />

A 68 F<br />

(a)<br />

(b)<br />

twisted<br />

spun<br />

yarn<br />

twisted<br />

filament<br />

yarn<br />

untwisted untwisted<br />

spun yarn �ament yarn<br />

Figure 4.1<br />

Twisted (a) and untwisted (b) spun and filament yarns.<br />

unlike spun yarns, contain fibers of infinite length, they<br />

do not need to be highly twisted. Most filament yarns<br />

are of low twist (enough to hold the fibers together) to<br />

provide a smooth, lustrous surface. However, filament<br />

yarns may be tightly twisted, thus producing special<br />

effects such as crepe. (See Figure 4.1.)