Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

knife<br />

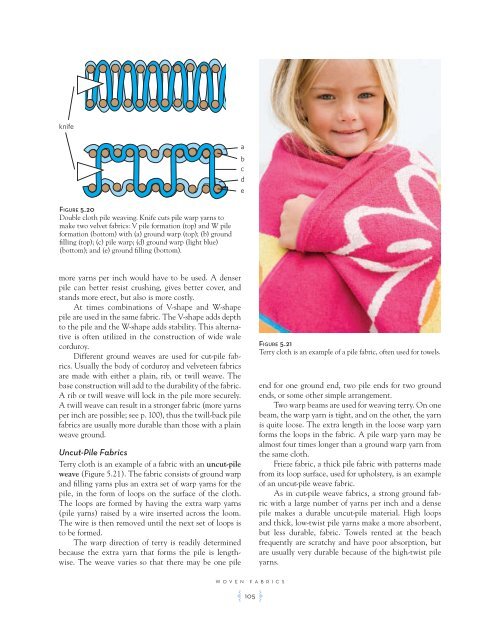

Figure 5.20<br />

Double cloth pile weaving. Knife cuts pile warp yarns to<br />

make two velvet fabrics: V pile formation (top) and W pile<br />

formation (bottom) with (a) ground warp (top); (b) ground<br />

filling (top); (c) pile warp; (d) ground warp (light blue)<br />

(bottom); and (e) ground filling (bottom).<br />

more yarns per inch would have to be used. A denser<br />

pile can better resist crushing, gives better cover, and<br />

stands more erect, but also is more costly.<br />

At times combinations of V-shape and W-shape<br />

pile are used in the same fabric. The V-shape adds depth<br />

to the pile and the W-shape adds stability. This alternative<br />

is often utilized in the construction of wide wale<br />

corduroy.<br />

Different ground weaves are used for cut-pile fabrics.<br />

Usually the body of corduroy and velveteen fabrics<br />

are made with either a plain, rib, or twill weave. The<br />

base construction will add to the durability of the fabric.<br />

A rib or twill weave will lock in the pile more securely.<br />

A twill weave can result in a stronger fabric (more yarns<br />

per inch are possible; see p. 100), thus the twill-back pile<br />

fabrics are usually more durable than those with a plain<br />

weave ground.<br />

Uncut-Pile <strong>Fabrics</strong><br />

Terry cloth is an example of a fabric with an uncut-pile<br />

weave (Figure 5.21). The fabric consists of ground warp<br />

and filling yarns plus an extra set of warp yarns for the<br />

pile, in the form of loops on the surface of the cloth.<br />

The loops are formed by having the extra warp yarns<br />

(pile yarns) raised by a wire inserted across the loom.<br />

The wire is then removed until the next set of loops is<br />

to be formed.<br />

The warp direction of terry is readily determined<br />

because the extra yarn that forms the pile is lengthwise.<br />

The weave varies so that there may be one pile<br />

a<br />

b<br />

c<br />

d<br />

e<br />

WOVEN FABRICS<br />

A 105 F<br />

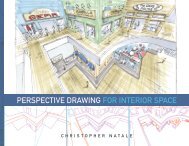

Figure 5.21<br />

Terry cloth is an example of a pile fabric, often used for towels.<br />

end for one ground end, two pile ends for two ground<br />

ends, or some other simple arrangement.<br />

Two warp beams are used for weaving terry. On one<br />

beam, the warp yarn is tight, and on the other, the yarn<br />

is quite loose. The extra length in the loose warp yarn<br />

forms the loops in the fabric. A pile warp yarn may be<br />

almost four times longer than a ground warp yarn from<br />

the same cloth.<br />

Frieze fabric, a thick pile fabric with patterns made<br />

from its loop surface, used for upholstery, is an example<br />

of an uncut-pile weave fabric.<br />

As in cut-pile weave fabrics, a strong ground fabric<br />

with a large number of yarns per inch and a dense<br />

pile makes a durable uncut-pile material. High loops<br />

and thick, low-twist pile yarns make a more absorbent,<br />

but less durable, fabric. Towels rented at the beach<br />

frequently are scratchy and have poor absorption, but<br />

are usually very durable because of the high-twist pile<br />

yarns.